We’ve been covering CEB presses lately. I found an excellent blog that describes in detail how to greatly enhance a basic CEB press. The Propagelle Projects Blog explains how they’ve modified a CEB press for improved performance. I’ve taken the liberty to include a few snippets and images to highlight the caliber of their work. Be sure to visit their blog for complete info.

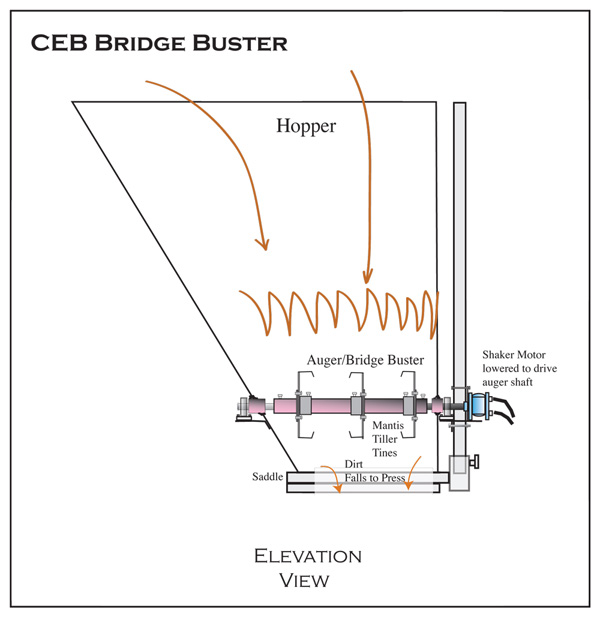

“Whenever a pile of finely sifted dirt is dumped into the hopper on a large CEB machine, that soil slips down the sloped sides and comes under pressure from the pile above. The lower dirt forms a bridge under pressure—regardless of how well sifted the soil might be.

We now have designed an auger with carbide teeth inside the hopper that will be turned by the Shaker motor. We will place this auger just above the block chamber so when it turns the dirt uniformly falls into and fill the chamber for pressing.

The CEB presses require 2,200 psi of hydraulic pressure to operate. I had originally thought I would use a large tractor and its established hydraulics. I could unhook the kwik-couple units from the seat and then free the tractor for hauling bricks and re-loading soil to the hopper.

Well, experience taught me quickly that those extra steps were tiring, so we tried another option: retrofitting an old mower. I had an 26-HP Briggs Stratton mower on a frame and so we converted that to produce all the hydraulic power we need and more.

CEB automation: In order to make a large number of blocks of very uniform size, a machine must be automated. While the block machine in the picture can be manually operated, automation frees up one individual who does not have to stand there in mind-numbing repetitive motion trying to get exact movements every few seconds. But getting this thing automated has not been easy.

The controller program not only signals each stage of operation with LED lights, it gives a read-out on the LCD screen of exactly what is occurring. I can operate the system with the two red buttons in the controller box or turn it loose for totally automatic “stepping.”

How Many Blocks a Minute?

While automation makes this machine very fast and accurate, it does not translate into so many blocks a minute—which is how most machines are advertised. That figure is meaningless when you consider that you have to dig up soil, screen it, mix in cement or lime, add water, and then press the blocks, move them to a pallet and shrink wrap them. Thus, a far more reasonable estimation of any block-press efficiency might be how many blocks a crew of two can produce in one hour, averaged from what they produced over the last eight or ten of steady work.”

Read the complete articles at the source: Propagelle Projects Blog

More good CEB sites:

Adobe Machine.com

EarthTek