Most of the housing solutions we discuss here at Natural Building Blog utilize ultra low cost materials such as soil for earthbags, adobes or CEBs, poles from local forests, straw bales and other locally sourced sustainable materials. Houses built like this are very strong and durable. They’re primarily for permanent housing. But what if you need temporary housing to live in while your main house is being built? While a mobile home/camper would suffice, consider the benefits of building temporary housing. The temporary housing solution outlined here is designed for speed and ease of construction at low cost.

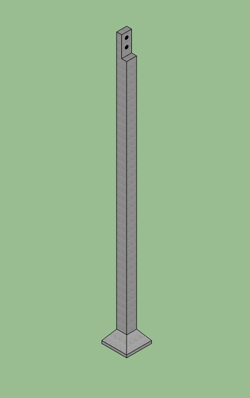

Your first thought may be why concrete posts? They’re not affordable or sustainable, right? Actually, it depends on the situation and where you live. We’ve already discussed various methods of building with wood posts. (Use the search engine on the right to locate previous blog posts.) This blog post will examine using concrete posts, because wood posts are not always available or practical. Larger diameter wood is becoming increasingly scarce and expensive, and some areas have severe termite and ant problems, and high rainfall that can quickly rot most woods. For these reasons and more, concrete posts have become very popular, and many hundreds of thousands of structures are built this way in tropical climates.

Some additional benefits of concrete posts:

– Numerous sizes, lengths and designs readily available in certain countries. Where they are popular, you can often find a small shop (local cottage industry) down the road that will make just what you need at reasonable cost.

– Can be used immediately. No need to harvest and transport wood long distances, peel the bark, wait for wood to cure, etc. This also reduces local logging.

– Very little excavation required. Dig small post holes about 12”-16” square by 18” deep.

– Built-in footer adds strength and stability, and can eliminate need for separate footer.

– Notches and holes cast in the concrete make it easy to attach beams with bolts.

– Can be sold later for about the same as the original cost or reused on another structure on your homestead.

– Can last for decades since they are rot and insect proof.

One possible design for a small, simple temporary house in a tropical climate:

– Set concrete posts about every 8’ apart.

– Bolt on beams to top of posts (can be milled, roundwood or recycled wood).

– Shed roofs are the easiest and fastest to build. Frame the roof so one side is higher.

– Bamboo or small diameter roundwood can be used for the roof and other framing members.

– Small diameter roundwood trusses can be pre-built to speed construction.

– Add wood or bamboo framing between posts as needed for windows and doors.

– Bamboo mat is one low cost, sustainable option for covering walls in tropical climates.

– Metal roofing or thatch panels are fast, lightweight and easy to install. The metal roofing could be reused on another building.

A 12’x24’ temporary house like this could be built in less than one week with two workers. Costs will vary considerably depending on where you live, but here’s one rough cost estimate:

$200 thatch panels

$150 concrete posts

$100 wood poles

$100 bamboo mat

$50 bolts, fasteners and miscellaneous

Recycled door, windows, hardware

$600 total

here’s how we make concrete posts:

http://www.velacreations.com/shelter/building-materials/fabric/item/57-fabric-formed-posts.html

fast, easy, cheap

Very good. Fabric forms were discussed on my Geopolymer blog. geopolymerhouses.wordpress.com/

It would not be difficult for someone to build their own ferrocement posts.

I would suggest using a length of 4″ PVC drain pipe as an inner form.

Glue end caps INSIDE both ends of the PVC pipe (see the EMAS videos for ideas how to make your own custom end caps out of another length of the same pipe), and insert a standard tire inflation valve stem in one of the caps. Inflate the pipe to 3 or 4 lbs psi to slightly expand the PVC pipe.

Then wrap that pipe in chicken wire, or stucco mesh. Apply cement mortar by hand, and then wrap the outside with plastic wrap. (stretch wrap such as is used in wrapping materials on shipping pallets would be ideal, but pretty much any plastic tarp or even garbage bags would work.

After it has set for a few days, release the air pressure from inside the pipe, causing the pipe to slightly contract. Slide the PVC form pipe out of the ferrocement post and reuse to make the next post.

Should be able to make a ferrocement post for a few bucks each.

Keep in mind that if someone wants a stronger post, they can install the hollow ferrocement post by hand, and then fill it with concrete mix later to make a full thickness concrete column.

A similar technique can be used to make other very useful items. For example, only wrap half the diameter of the pipe with wire mesh, and cover with ferrocement. You now have a custom rain gutter.

Using shorter pipes, sliced in half lengthwise, and mounted on a board with one end spread slightly to make a half conic section, one can use the half pipe technique to make ferrocement roofing tiles that look a lot like spanish clay tiles, especially if one adds iron oxide to the cement mortar mix to produce a reddish brown cement color.

The possibilities are endless.

For lots of inspiration about those possibilities… see http://www.flyingconcrete.com/ (a website often referred to on this blog. Rightfully so.)

Those are all super good ideas, Jay. I’ve known about Flying Concrete for a long time, but haven’t heard of these particular building methods. Maybe we should turn the fence post idea into a separate blog post so everyone sees and understands the process better.

One small variation on the fence post idea. Do as you say but then add a pipe down the center and put cement between it and the fence post. That way you don’t have to fill the whole thing with cement. The amount of cement could be adjusted by the size of the center pipe. Plan ahead so the pipe is easy to pull out. Coat the pipe with oil, have it protrude above the fence post, drill holes for a rope pull and slide it out after the cement has set up.

In case you are interested, the TV Show “How It’s Made” showed how commercial manufacturers make concrete lamp posts.

http://youtu.be/XavLVql5NZQ?t=16m27s

Clearly my suggested method for thin wall ferrocement poles would not be nearly as strong as those, but they also would be drastically lighter and cheaper.

Owen, I am uncertain if your oil idea as a release agent will be sufficient. I’m not saying you are wrong, just that I’m unsure.

Concrete warms as it hydrates in an exothermic reaction, but then cools and contracts as it fully cures. That cooling and contracting will apply some pressure to an inner core form. It is possible that pressure will induce too much friction for the oil to overcome when trying to withdraw a PVC pipe from the center of a hollow ferrocement pole, especially a longer pole that will have a lot more surface area, and hence more friction.

Then again, you may be correct. I simply don’t know for sure. I recommend experimentation for anyone attempting this method to discover the details of the technique that will make the work go fast, easy, repeatable, and of course successful. The person that figures it out first should post photos or even better, videos of their success for others to admire and duplicate.

Dang it Owen… now you are trying to piss me off, aren’t you?

Now my brain can’t stop thinking about whether it is possible to build massive ferrocement tinker toys.

http://ecx.images-amazon.com/images/I/51DRCT06DJL._SL500_SS500_.jpg

I’m going to be laying awake at night thinking about what method might be cheap and easy to build big ferrocement hub rings to connect the hollow ferrocement poles together to make giant tinker toys now.

Sometimes, Owen, you can be a real pain in the neck!!

(In a good way.)

Drats.

That YouTube link was supposed to start at 16:27 into the video. If you click on it and it starts at the beginning, fast forward to 16:27 to see the lamp posts being commercially made.

I don’t know why YouTube’s “start at” feature isn’t working today. Sorry bout that.

Excellent video on the lamp posts! (It may sound boring, but I assure you it’s not — at least not if you’re interested in how things are made.) Now that is some Might-y-Fine looking concrete. Let’s just hope they don’t test every lamp post like the one at 21:05.

Hollow posts: I think a lubricated (recycled oil, etc.) PVC pipe will come out if you do it soon enough. Don’t wait any longer than necessary. Experiment a bit to see what works best.

Cool idea!

If anyone wants to test this theory I have vacant land in Rio Rancho NM :)