Open Source Ecology is a network of farmers, engineers, and supporters building the Global Village Construction Set — a modular, DIY, low-cost, open source, high-performance platform that allows for the easy fabrication of the 50 different industrial machines that it takes to build a small, sustainable civilization with modern comforts.

Key Features of the Global Village Construction Set (GVCS):

Open Source – Low-Cost – Modular – User-Serviceable – DIY – Closed-Loop Manufacturing – High Performance – Heirloom Design – Flexible Fabrication

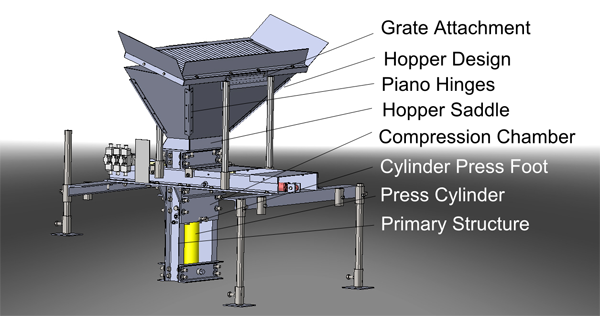

Liberator CEB Press (one of the 50 machines in the GVCS): a high performance machine for producing Compressed Earth Blocks (CEB) from onsite soil, at production rates of up to 16 bricks per minute.

Source: The Factor E Farm Blog

Open Source Ecology on Facebook

Liberator CEB IV – Open Source Ecology drawings and specs

Open Source Ecology Forum (interesting, but not much on CEBs)

Propagelle Project

My fiance and I are in the planning stages of building a castle in Tennessee. We wish to keep the build as natural, and cost efficient as possible.

Would the CEB machine brick offer the integrity we need to build a structure that will be 4 stories high in it’s highest tier, and have an approx. 3500 SQ. Ft. foundation? Stone is the traditional choice, but a veneer system is definitely more cost effective.

Thank you for your thoughts.

Yes, this is possible. Just realize you will need a fairly large workforce to do this project. If not you will probably get bogged down for years. This is VERY common. Also, you will want to get an engineer. This will be money well spent in this case because you’re dealing with a complex structure. They can tell you exact details that are appropriate for your area. And obviously you will need a large machine that can churn out thousands of CEBs if you can’t buy them locally. Be sure to do a careful cost analysis on the whole project before starting. Yes, CEBs are low cost but you need to add in a bobcat, the CEB machine ($100,000?), a large workforce of masons, etc.

I am very interested in getting the plans to build the newest version of the liberator press.

Check their website.

Hi,

I interested in buying one of these CEB machines or a parts kit,

but cannot seem to be able to log in to their website or find a working email address.

Please help me make contact with them.

Thanks,

Dan Katz

Interested in purchasing a machine already built.

Yes, can I find ceb machine for sale

Liberator 4 in use.

2513 Bricks to build a “Microhouse”

http://vimeo.com/75956538

Exterior Plastering

http://vimeo.com/76072697

(Nice video, too bad so many people are standing around gawking instead of helping do the work. heh heh. I’ve been on too many projects like that.)

Raising the Roof

http://vimeo.com/76471481

Finishing Touches

http://vimeo.com/77411242

Lots and lots of trips up and down an extension ladder.

“it appears no cement is necessary in the CEBs”

Absolutely false. There is always at least 10% cement minimum in the mix, not including the poured full concrete foundation.

Hello,

I want to build a CEB press.

Please as far as possible if you can tell me where I can get a sketch, a plan to build a press like this.

Thank you,

Lucian Postelnicu

See DirtCheapBuilder.com (scroll down a little). http://www.dirtcheapbuilder.com/Home_Building/Earth_Block_Construction.htm

This is an older, simpler design. New machines are more powerful and make stronger blocks due to greater forces applied through leverage. It should still work okay.

If you desire a press just like the one featured in this blog post, the plans are available on the Open Source Ecology website linked to in this post. That is what “Open Source” is all about after all. Free distribution of the designs and information to anyone who wants it.

Just go to their website and look up the plans.

Also, here is an update about the Liberator 4 CEB press featured in this blog post.

They have finished building it.

Check out their video.

http://vimeo.com/57424944

I’d appreciate knowing of any business case studies that profile the use of this machine in the marketplace. Does it outcompete other building systems in certain areas?

Any input from those who’ve replicated this machine is welcome.

Here’s the price as of Oct. 30, 2012:

The cost is $9k FOB Kansas City. (power unit not included)

Ordering involves submitting payment in full, and production run is 30 days from your payment. You have the option to participate in a production run, which takes 2 days with a hyper-optimized Collaborative Production Run with 8 people. See Blog: http://blog.opensourceecology.org/

Marcin

In case you haven’t figured it out, I’m very interested in learning more about the Liberator block press and possibly building one. Open Source Ecology may have one of the most efficient building systems in the world if their CEB machine does what they claim. CEBs are very popular worldwide. The soil is cheap and readily available in our area. Their building system eliminates 90 some percent of the labor. There’s no rebar and mortar through the wall as with hollow interlocking blocks (they’re just simple rectangular blocks). There’s no separate drying process, which normally requires multiple steps of carrying and turning. The blocks are put immediately into the wall with a thin coating of mud to ‘glue’ the blocks in place. The machine is parked right next to the house and the blocks are stacked immediately. You could build the walls of a small house in one day according to them. They provide the CEB press plans for free. They’re on their 4th iteration, so I think they have a pretty good machine now. The parts cost about $1,500 in the US. The finished machine sells for $25,000 in the US. I estimate it could be built in developing countries for around $1,000 labor. Again, I think this machine has enormous potential. It’s far less expensive than most construction methods. It’s less labor intensive than most natural building methods. The walls are fairly thick and so it will be cool inside in hot climates (with wide roof overhangs). You don’t need to be a mason to build the walls, which means you could hire just about anybody to carry and stack the blocks.

Additional benefits:

– it appears no cement is necessary in the CEBs. Just like rammed earth, the 20 ton compression would make the blocks very strong and impervious to insects. (This assumes adequate clay content. Our CEB soil is low in clay and may need some added.)

– it appears that the extra machines typically used to pulverize and mix the soil aren’t necessary. (See Star Top price list https://naturalbuildingblog.siterubix.com/more-info-on-compressed-earth-blocks-cebs/) This saves money on machines, maintenance and labor, and greatly speed construction by eliminating several steps.

– posts could be cast inside the wall if necessary after the blocks are stacked. I’ll be posting a drawing soon that shows the process.