As many readers know, my passion is promoting very low cost housing that virtually anyone can afford. Earthbag is a natural option for housing the poor, however the thick walls take up a disproportionate amount of space on tiny urban lots such as in slums, and the hard work deters some. Thin walls have a lot of advantages. That’s one reason Dr. Anderton’s E-khaya housing system with narrow earthbag tubes caught my eye. I’m now considering how to adapt this basic method for wider use.

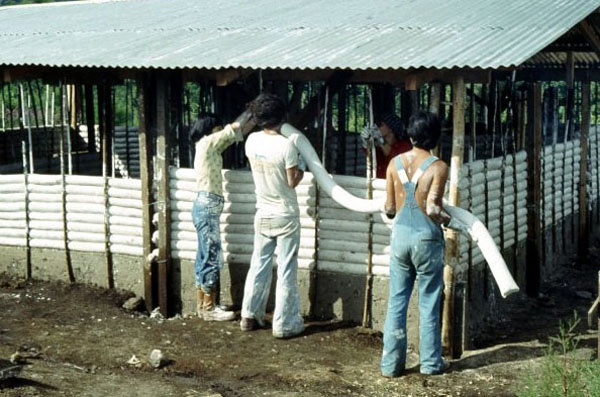

This is not exactly a revolutionary idea. The building method goes back to the original earthbag houses built by Gernot Mincke in the 70’s. (Other than the military, Mincke was the first to build earthbag houses as explained on our History page.)

The concept is so fast and simple that this could readily catch on with earthbag builders. A 10’x12′ room could easily be built in 5-6 days. Kelly and I and others have steered earthbag building toward thick, self supporting walls. That’s fine if you need lots of insulation and have adequate space. But many people complain about the thick walls taking up too much space in crowded cities. This is where Mincke’s original idea really shines!

Thin wall earthbags will work on most simple house designs. That includes rectangular houses, round, organic shaped, all types of roof designs, whatever. Ex: someone has a plan designed for CEBs or wood walls. They could use that plan and just replace those materials with thin wall earthbags (narrow tubes).

Here’s the basic building process using the materials we have:

Use 3″ wood poles at corners and on each side of door and windows. (24” spacing on larger structures.) Wrap the bottom of poles in plastic and set in small post holes filled with concrete. Screw 3″ poles along the bottom and top between posts and around door and windows. Then attach diagonal 3/4″ wide bamboo lath to the poles with a nail gun. Make tubes in advance. Various types of fabric and any number of fill materials (lava rock, etc.) could be used. Sand is ideal in some ways, particularly for poor areas. It’s freely available and can be poured in the tubes using a funnel (much easier than working with soil that clumps and compacts). Sand will naturally stiffen when the tube is full and won’t turn to mud if wet. Tie the tubes to the lath with twine or wire. Add the roof (we would use recycled wood, but could use bamboo, etc.). Metal roofing is good. We’d use microconcrete roofing tiles (MCRs). Then add the door and windows and plaster. Optional fishing net (very cheap) could be stretched around the outside. Optional perlite or other type of insulation such as recycled ground foam insulation could be added as shown by Dr. Anderton.

Lightweight, thin wall earthbags is a game changer in part because it empowers women to build their own homes. Typical earthbag building is labor intensive. Thin wall earthbag is around 10 times faster and easier.

The cost of this system is a huge plus. Fewer materials means lower costs. Faster construction means less labor.

Now I’m considering another workshop, maybe in December 2014. There’s nothing definite at this time. I thought I’d propose this to readers to see how many people are interested. What do you think?

Image: History page at Earthbag Building.com

Hi Owen thank you for your inspiration.Im so excited about e-khaya building system.Could you please send me more details about e-khaya.

You’ll have to contact them. And I agree, it does seem like a very exciting building system. I’d love to hear an update if you get the latest news.

hi owen, i sent a reply earlier today but i dont think it got through so if this is a duplicate i am so sorry. i spoke with the university of tennessee today and they suggested i get in touch with a certain dept.at the university and try to get my future rice hull earthbag home presented to the county as a research and developement project for the university. my county will not approve this building type. i will definately let you know if it works but do you know of anyone that has gotten approval in the u.s. for rice hull construction? im sure they would approve it as just an insulator but i want to use it as load bearing. i read your info and i understand now how it works. i need to get some information together to sell the university on this idea. do you know of any dept. or individuals i can talk to who have had experience with this? i read an article from cookeville tn. that proved the better insulative and moisture retaining properties but the study did nothing to support a load bearing structure idea. any help would be awesome! thanks again and you have already been a great help!

Your other comment came through okay. You won’t be able to sell the loadbearing concept because there are no tests to verify the capability. You’ll need some type of structure to reinforce the walls. Refer to my most recent article about building with rice hulls: https://naturalbuildingblog.siterubix.com/rice-hull-tubes-between-double-steel-pipe/

hi owen, just thought you might like to know i contacted the university of tennessee and they brought up an intriguing idea. my county has building codes that im sure wont approve earthbag building, especially not rice, so they suggested that we present the project to the county as a research and developement program sponsored by the university. so if i can contact the right dept. and get them excited about it then they may go for it. students would be involved in the process. just thought id pass this idea on. maybe someone else can benefit from help from their local university. i will let you know what i find out from UT.

hi, im so excited about this idea but i live in the smoky mnt. area, extreme cold sometimes. could i make one layer of sand clay mix on the inside and a layer of insulation on the outside? do you think it would hold up?

I suggest insulating walls around 15″ thick made with lightweight insulating materials such as rice hulls. So you normal sized tubing or bags but fill with lightweight material. This requires a frame or some type of reinforcement so the walls are stable. See yesterday’s blog post about using galvanized pipe for wall supports and one example. You could also use wood posts, rebar, etc.

Making double walls is unnecessary extra work. The interior plaster, floors, wood stove, etc. will provide sufficient thermal mass if the floor and roof are adequately insulated.

thanks for the reply! so let me make sure i understand…i can use this smaller tubing on the inner side of walls (sand and clay)but use a normal size bag or tube for the outer side of walls (insulating material) but just make sure to brace it up good? i couldnt find the comments about the rebar but i get what you are saying.thanks so much for this advice! wow, i just realized how thick my walls will be! lol so worth it though.

No. I said making double walls is unnecessary work. Make 15″ walls of tubes filled with insulating material.

Search previous blog posts for ways to reinforce earthbag walls with rebar. One excellent article is called Scoria Casita. His videos explain every detail.

*****Anybody can do this if you live in a non-code area!!!!! It’s 10 times faster and easier than working with heavy earthbags. Rice hulls are as light as popcorn and virtually free in many areas. Just do it! Document your project and share with others.

thanks! i will check it out.

Owen,

One more question – these lime-soaked natural fabric bags shown in the image for this post – how durable are they? I mean, I know that they’re strong, but do you know how long they hold up?

I don’t really have soil where I live – just inert sand and chalk, so I’m wondering if non-biodegradable bags are necessary apart from (maybe) for the foundation.

You have to start doing some tests using what you have available. That’s the key — use what’s low cost, locally available, easy to get, durable.

Hi Owen,

This seems like a great idea. Do you know if it has been attempted in any hurricane-prone locations?

It would be safer to go with thick wall methods such as typical earthbags in disaster prone areas. Better safe than sorry. Almost nothing can withstand the direct hit of hurricanes and earthquakes, so it’s best to build as strong as possible.

What size of bags would I need to get for this and is there a new blog post on it?

Search for local brands and see what’s available. Shipping the bags really adds to the cost. Some bag suppliers will sew custom sizes. Tubes are best. In a developing country, you could hire a local seamstress with a heavy duty sewing machine to make small tubes from bigger tubes. No blog posts on this recently except the earthbag water tanks use this same concept. That supplier is in Australia.

Can you tell us more about this? I’d love to find out more

details.

Email me for details if you’re serious about building this way. Right now I’m working on a drawing to show the main parts.

I was curious as to how warm these wall are? I live in the northern part of the world. We have cold weather and lots of snow

Use typical 15″ thick earthbag walls filled with insulating material such as perlite. Thin wall is for milder climates. Read my insulated earthbag house Instructable. http://www.instructables.com/id/How-to-Build-an-Insulated-Earthbag-House/

It would have been nice to see the comparison to cellulose insulated walls, which I think would have done better, but maybe not as well as SIPs?

This kind of reminds me of the two channel tubes/bags used in S Africa. Any updates on that particular method? Did they get their production off the ground. I seem to recall that they were going to try marketing bags.

I think that system is still plugging along. But it seems Dr. Anderton’s focus has shifted to the small diameter tubes for e-khaya since they’re smaller, lighter, faster, less expensive.

@Tod I thought I might clarify something. Hyper adobe is using mesh bags. They look like onion sacks. It was developed in Brazil. Super adobe is the term coined by Nader Khalili at CalEarth. It uses poly tubes or sand bags. I found a supplier in NY offering 18×30 bags for around 30 cents including shipping to the West Coast. 18inch tubing runs about 80 cents a ft and that is ordering it from a manufacturer, not purchasing at Cal Earth. Separate bags are cheaper and much easier to use then the tubing. One person can build by themselves. The large tubing requires at least 2-3 people to build with.

The key difference is how many people are available. Bags are ideal for 1-2 people. Recycled bags are often available. Tubes are faster for larger crews but require buying new.

Sounds good for something using less insulation. Now its what is practical material/source for smaller tubes?

If you have the backing of bamboo lattice or fence. some sort of stucco would work and while thinner, would be easier and faster to build walls with.

Stay tuned for an upcoming blog post that will explain how to make tubes out of recycled bags.

Hyperadobe is too costly for our limited budget unfortunately. I saw the bags on calearth.org – nice bags but wow are they pricey. My thinking is that if I make 100 earthbags for 30 days, I’ll have 3000 earth bags. in 90 days. If I can make one earthbag in five minutes, then in one hour, I’ll have twelve earthbags. So if I have another set of hands helping, we can have our 100 earthbags together in about 5 hours in one day, not counting breaks, etc. Not everyone is comfy with a small house or a dome/round house. When you consider the benefit of not having a mortgage (low end $800/mth) the five hours a day don’t seem so bad for 30 days. Someone posted that 1000 earthbags makes 700 sq feet of wall space, so 3 times that would be 2100 sq feet of wall space = 4 exterior 40 x 8 walls (1280 sq. feet of wall space) (about the length of a shipping container plus some walls for inside) = 1600 sq. foot house. Reasonably speaking, this could be completed with about $5000? The exterior could be secured with ferrocement and remesh, cured well for the maximum 21 days-28 days? So the house could be completed in six months. Is it possible for a poverty line family to have affordable housing that they can live quite comfortably in. Can I do that? Numbers seem to show that it is possible.

I don’t have time to crunch all those numbers. Stay tuned for future blog posts about thin wall earthbags that promises to be much faster and much less expensive than regular earthbags.

They only use the posts during the construction process. Once the roof is on, they remove all of the posts and bracing. So those thin earthbag walls with their concrete plaster skins are load-bearing.

http://www.e-khaya.com/index_htm_files/182.jpg

Yes, that’s right. Their system is ideal for building lots of houses that are the same size. What I’m talking about here is more flexible and probably more suitable to most readers of this blog who want to build an affordable home. Stay tuned for more blog posts on this topic.

This is very interesting. I had NO idea that the original idea is from the 70s. What’s even further NOT understandable is why earthbag building never took off big time. It probably was frowned on and looked upon as some hippie idea. We’ve been right about a LOT of things now haven’t we?! Thanks Owen for the post. Go for it!

New ideas take a while to catch on. People are used to doing things a certain way and are reluctant to change. Housing is expensive and people don’t want to run into problems. It’s only now that the momentum for building with bags is really catching on. Anyone can plug the term into a search engine and see thousands of websites, videos and projects all over the world. I’m hoping (and predicting) that thin wall earthbag construction will give the movement another big boost.

I saw a hilarious poster on the Internet about Hippies were F*%#! right about a lot of things.

Thanks for bringing this to our attention, Owen!

This is a technique that will spread. So glad Dr. Anderton has taken this forward!

Sand in woven tubing, sticky clay in open mesh wattle tubes. Pouring sand is easier than filling with damp clay, but the clay will have additional stability and may allow lighter outer wall reinforcing.

I’ll be exploring the structural effect of this using 8″ diameter wattle tubes (that make a 7″ thick wall). It’s what I used for the 24″ high base of my trash wattle arch. I’m about to use it as a base for a straw wattle site wall.

Some areas will want to use bamboo or light rebar for the verticals.

I can add that plastic trash is also possible as fill, although sand is more stable and will reduce the amount of earth, stabilized earth or cement needed for stucco.

Another comment rescued from the spam folder. Our web host is sending lots of comments to spam.

Yes, as Patti points out there are quite a few options. Learn the options and use what makes most sense in your area.

3″ posts are for the small shelters I’m envisioning. 4″ posts are standard for most houses.

Owen

Great idea. I have a good material to use for the tubes in my unique area. I can just roll it up into tubes, stand it on end and fill it like a cylinder. I have read Mincke’s book and it is very good. Lots of detail provided.

This would even work well for internal walls.

If you were to use sand, what is your current thinking on how wide the tubes should be?

I rescued this from the spam folder. I’m still finding comments in the spam folder almost daily.

Size of tubes: This depends on your climate, what fill material you want to use, etc.