Owen Geiger and I have just found that a book published in 1990 in Germany, Building with Pumice, written by Klaus Grasser and Gernot Minke, describes experiments done in the 1970’s at the Research Laboratory for Experimental Building at Kassel Polytechnic College in Germany that have considerable bearing on the history of earthbag building.

Most of the book is about the physical properties of pumice, how to obtain and process it, and how to make blocks or walls with pumice/cement, but the fifth and final chapter, titled “Building with Unbonded Pumice,” describes how they began to investigate the question of how natural building materials like sand and gravel could be used for building houses without the necessity of using binders. The use of fabric-packed bulk material was found to be a cost-efficient approach. They used pumice to pack in the bags, because it weighs less and has better thermal insulating properties than ordinary sand and gravel. Their first successful experiments were with corbelled dome shapes ( an inverted catenary) which was obtained with the aid of a rotating vertical template mounted at the center of the structure.

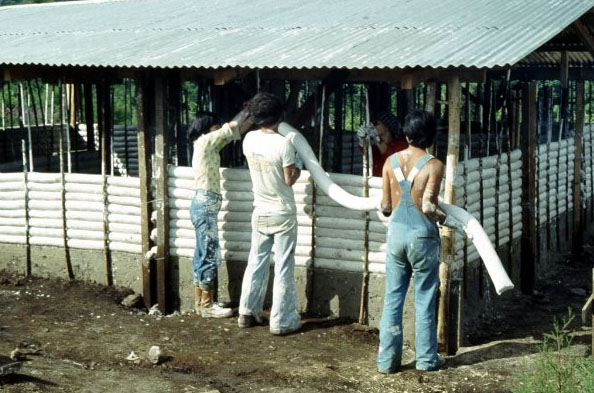

1978, a prototype house using an earthquake-proof stacked-bag type of construction was built in Guatemala. They used cotton bags soaked in lime-wash to protect the material from rot and insects. When flattened, the bags measured roughly 8 X 10 cm. Vertical bamboo poles placed on both sides of the bags and interconnected with wire loops gave the stacked bags stability. The bamboo rods were fixed to the foundation and to the horizontal tie beam at the top.

Obviously the concept of constructing homes with fabric bags of mineral material predates Nader Khalili’s earliest experiments by many years, and I was certainly not the first to experiment with filling earthbags with pumice! The entire chapter is reproduced as an article at www.earthbagbuilding.com.

This is intresting i need to start building houses using pumice because its available at my home.My main aim is to build using pumice walls kindly inform me more on the same thanks in advance.

Search this blog for keywords scoria or pumice and you should find everything you need to know about building with lightweight insulating scoria bags or pumice bags. Just fill 18″ wide sand bags or tubes with crushed scoria or pumice. The best project so far is called the Scoria Casita: https://naturalbuildingblog.siterubix.com/earthbag-scoria-casita/ Read this carefully and watch all the videos this guy has made. It’s important to add rebar, buttresses, etc. to help stabilize the walls.

Hi there,

We’re huge fans of pumice crete and rammed earth construction. We’ve written up some basic information on our process here:

http://www.tierraconceptssantafe.com/2010/04/alternatives-rammed-earth-pumice-crete/

On our website we’ve got contact information if anyone wants more information on our techniques or recent green construction work.

Found Syfilco tubing(Bags) Syfilco Ltd., Exeter, Ontario. 2500 feet at $.15 a ft comes to $375.00 enough to build house. This material will eliminate need for barb wire use due to pouris bag material adheres to next layer and dries hard(Big Savings. Material also treated with sunblock material. Also see use and videos of building and tips at

Hyperadobe Step-by-step sight, mulhere-ecia-blogspot.com. This was great info and seeing it got me very excited to start building my 2bdr round home this summer in Maine. Also going to make round cylinder column(out of filled tube bagging) in center of house to place stove pipe in for wood stove and this tower will also be used to support roof timbers from center of house to outer wall for roof support. Hope this info helps and encourages building with this material, God bless and good luck.

Owen,

I found some 22×36 woven poly bags. Would the walls be a little more stable but still insulated enough if I went with a 50% road base or soil and 50% scoria? I was also thinking of getting 16-24 10′-12′ sections of rebar, driving them down in the soil through the rubble trench. 8 pairs with one section interior and one exterior, tied together through the courses with bailing wire. The rebar and wire will stay and be plastered over. I was thinking the rebar would go high enough above the wall that it could be useful in aiding with a bond beam as well as giving the wall more stability since i’ll be using such a high scoria content. I also just like to overdo things as well. Thoughts?

Yes, sounds good. This will stiffen the wall a lot and tie into the bond as you say. You can email me at strawhouses [at] yahoo.com to discuss any other details.

I can only imagine what the major announcement is. Can I get a hint as to how long the wait will be on the announcement? We aren’t planning on any sort of ground breaking until spring 2011 so we have a little time. Thanks for the help.

We hope to share some good news in 2-3 weeks. We’ll see.

My wife and I recently bought 5 acres in the san luis valley of colorado in costilla county. We will be building the 2 bedroom roundhouse. I’m just curious as to any mods we should consider as far as the proper mix for the bags to insure we are properly insulated. Also, we were thinking of making it a flat rooftop terrace type of roof. Are there any books/sites/dvds that you know of that might help with those mods or is that a possible mod to purchase when buying the plans?

I recommend using scoria in the bags for your situation. This will create a superinsulated wall. Using soil is not a good choice in cold climates — it would be cold like living in a cave.

The walls won’t feel totally stable using just loose scoria. I would use wider 22″ bags for stability and temporary braces (2x4s or wood poles at 45 degree angle) to hold walls in position during construction. It will be very strong once the bond beam is on. Large roundhouses would benefit from external vertical 1/2″ rebar pins placed opposite each other and tied together with poly baling twine. Use 5′ lengths that overlap about 1′-2′.

Plus, I suggest waiting a short while. We have a major announcement coming up that will probably help you.

Kelly and I have written a fair amount about using scoria in earthbags. Search our sites and/or Google for details.

Hi, I’m interested to learn of any info regarding pumice-filled bag construction in cool, rainy climates- in my case, southern Chile, where rain can continue nonstop for a month, and wind-driven horizontal rain can pummel a structure for three straight days. Thanks for any help you can offer!

Scoria or pumice, both of which are volcanic rocks, will work perfectly for your situation. Just Google “Owen Geiger” and scoria. The main thing of course is locating a source near you to reduce transportation costs. Look for lightweight aggregates about 1/2″ in size. Good luck and please keep us posted on your project.

very unique idea on building a small house. that is really cool

I have another blog about green home building in general at my other site: http://greenhomebuilding.com/weblog/index.htm and I have been a guest blogger at http://www.homefinder.com/content/blog and at http://www.planetthoughts.org/index.cfm

The style of writing is very familiar to me. Did you write guest posts for other bloggers?

Okay, I’m a novice. this technology (if you will) really excites me. I see where many things can be corrected in poor and rich countries with this sort of thing, my question is how available are the materials that you are talking about. I can’t just walk into Home Depot and buy 3 tons of ground pumice for my walls or a dump truck load of rice hulls for insulating the outside of a bag house. SO now what??

Sourcing these sorts of materials must always be done on a local basis. Some areas of the country have volcanic materials easily at hand and some don’t. It is the same with rice hulls…if they are available in your area, use them. Otherwise you will need to find something else. Dirt is available just about everywhere. Polypropylene bags and barbed wire are available in most places around the world now.

Kelly and Owen got me involved with this information about building with pumice. I started out to find out how earthbag could be built with pumice in humid climates, and ended up by exploring the shapes of earthbag buildings made without any steel or cement.

I am firmly convinced that earthbags with lightweight pumice or scoria will become a standard construction technique in the exploding development of the hot and humid regions of Africa, South America, and Asia. Mr. Minke’s booklet about pumice details its use for montane or sub tropical climates where bamboo or wood can be used. In the humid tropics termites and rot prevent reliance on bamboo or wood.

The thought of rust attacking barbed wire (in these paces where humidity is often between 90 and 100%) kept me from looking into earthbag construction at first. But when I realized that the barbed wire is most needed to hold bags in place until the earth has cured and dried, the lights went on.

It seems irresponsible in very damp climates to rely fo strength on a material that may eventually rust. But once the walls are cured, the longevity of the barbed wire is not as critical. I think of the bags and wire as a sort of formwork. The earth itself is strong enough once it has cured.

In other climate areas, cement stucco on a layer of wire mesh provide additional strength, probably increased by the barbed wire used between courses. But in hot and humid areas cement stucco causes condensation and mold damage. In these areas earthbags can be used to enable quicker and simpler earth construction that will be accessible to many who cannot afford concrete.

I think I’ve finally finished my research into earthbag for the hot and humid regions and hope these booklets are helpful to others!

How did Minke’s test houses in Guatemala last? A follow up would be very impressive.

I don’t know…and agree that some follow up would be very useful.

How can pumice or mixed pumice and earth be stabilized without large cement coverings or lots of wood?

This is where the earthbags come in very handy, because they can hold the loose pumice in place, and then a thin earthen plaster can be used to protect the bag material. It is possible to make pumicecrete that will support itself, but this does use cement.

Walls need to hold little heat to prevent condensation between night and day temperatures in the very high humidity. Insulation to keep out high daytime temperatures is a plus.

Very thick earthen or masonry walls will work in some hot, humid climates (if they aren’t too hot), as they tend to create a very stable temperature over time. Condensation is usually only a problem when warm, humid air makes contact with a much cooler surface, and such walls are not likely to be that cool. But I agree that a fully insulated wall is really the best, and this can be achieved with earthbags filled with pumice. Termites are not interested in any of this.

Is there a proportion of earth to pumice that allows earthbag construction without additional wood, steel, or bamboo reinforcement? What specific heat and thermal conductivity would this mix have?

You can certainly mix pumice with earth, and the folks who wrote “Building with Earthbags” advocate this, but I don’t really see any advantage to doing so. This severely limits the insulating qualities of the pumice. Either of these techniques, however, require very little wood, steel or bamboo reinforecement. Usually just some barbed wire placed between the courses of earthbags is all that is needed to make very durable walls.

I do not have technical number for heat and thermal conductivity for these systems. My empiracal evaluation of pure pumice is about R-2/inch for the insulative value, and the more earth that is added, the less this number would be.

Hope this helps.

How did Minke’s test houses in Guatemala last? A follow up would be very impressive.

How can pumice or mixed pumice and earth be stabilized without large cement coverings or lots of wood?

Earthbag like other masonry fits into the dry tropical areas as an excellent climate responsive material to create indoor comfort without artificial temperature controls. The humid tropics have other constraints.

I am a volunteer designer working on training centers for national literacy workers and translators with Wycliffe Associates. Many of our projects are in the humid tropics. Termites often find ways through floors to devour wood structures in walls. Walls need to hold little heat to prevent condensation between night and day temperatures in the very high humidity. Insulation to keep out high daytime temperatures is a plus.

Is there a proportion of earth to pumice that allows earthbag construction without additional wood, steel, or bamboo reinforcement? What specific heat and thermal conductivity would this mix have?

Patti Stouter

Wycliffe Associates