“Tucson, in Pima County Arizona, has about 15% of all the burnt adobe homes built in the US from the 1960s through the 80s.

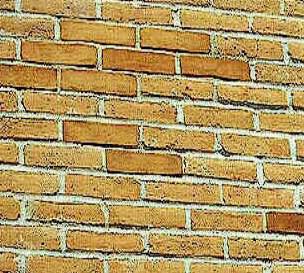

Basically, burnt adobe homes are bricks made out of mud that are much thicker and larger than typical bricks. The concept behind building with adobe is that adobe walls have enough thermal mass to absorb heat during the day and release it at night thus keeping the home at a fairly stable temperature year round.

Although the bricks will outlast you or me – it is important to care for them just as you would a wood or stucco home. Tucson has several companies that specialize in repairing adobe that is neglected and also those that treat and maintain the bricks with a special coating to maintain its beauty and keep the bricks intact.”

More at the source: Active Rain

566 burnt adobe house pics at Houzz (sign up required)

I live in Tucson in a burnt Adobe house built in 1958. It is solid! The temperature is super even all year round. My electric bill is $100 running a/c in summer. The bricks say Mexico on them. Makes sense they could come from Sasabe.

I am purchasing a 1957 frame\stucco home in southern AZ. I would like to strip the stucco, insulate, pour a brick ledge and lay burnt adobe. The structure is in good shape but I like the look of burnt adobe. Does anyone see any issue doing this??

Thank you

You need a foundation under masonry walls to carry the extra load.

Instead of stripping the stucco, the standard method is to drill holes and blow in insulation.

Thank you. I plan on installing a footer for the burnt adobe. The stucco is old and cracked. Taking it off only makes sense. I plan on using close cell foam for insulation before re-sheeting.

I need to replace a small number of burnt adobe bricks following plumbing repair. I have sufficient bricks but seek information on obtaining mortar mix that is almost white..Do you have suggestions for me?

Thanks! Don Heckerman 3445 Calle del Prado Tucson

Here in Southern Mexico they use coconut shells… very basic production tech, labor intensive, poor working conditions,Quality is not bad. Very friendly folks. You get about 4 bricks for a US dollar.

Saludos

Cato

How’s your project going? I was hoping you’d translate 1-2 paragraphs for a blog post.

According to Quentin Wilson, the adobe specialist at http://www.greenhomebuilging.com, when asked about a “burnt adobe” house in Tucson, Arizona, he said, “Chances are that the quemados were made in Sasabe, Mexico not to far over the border. They made kilns with a vault of unmortared adobes stacked loose. Raw adobes were placed inside and then a huge fire was built at one end and the flames and hot gasses went down the kiln to a chimney at the other end. It took a 5-ton load of firewood brought in on a flatbed truck and the firing lasted three or more days. Like the Romans, the Sasabeans were denuding their surrounding hillsides of trees and had to go further and further away to get enough fuel. I think the system lost its economic feasibility around 1975 just before I had a chance to see it in operation.”

“Once the firing was ended the vitrified adobes were removed. They were reddish/orange and clinked just like a standard brick. The adobes that had formed the vault were then stacked to be the next batch to be fired – a very clever technique on the part of the Mexicans. Quemados were waterproof to a large degree but the firing was not enough to make them resistant to freeze/thaw cycles so some deterioration would occur especially at the top (rain and snow) and bottom (rain backsplash or rising damp) of walls. In many cases they were used as a coping on the top of a raw adobe wall to stop moisture incursion from rain and snow. Quemados usually test higher in compression (about 550 psi) than their original raw form (about 300 psi).”

That explains a lot. One question though. Low-fired bricks (much smaller than adobes) are still made in Mexico. I wonder what fuel source is used to fire them? Maybe less fuel is required because the bricks are smaller?

In South Asia, low-fired bricks are often fired with rice hulls.

https://naturalbuildingblog.siterubix.com/low-fired-brick/

Regular adobe walls are fairly dark. Burnt adobe walls are lighter and yellowish. This method has never caught on in a big way as far as I know.