Patti Stouter of Build Simple, Inc. has been testing earthbags and writing technical reports for the last several years in an effort to improve strength of earthbag buildings in seismic areas. She asked me to forward the following announcement.

It looks like an engineering department near San Francisco will be completing needed tests of earthbag strength during 2018. If anyone wants to help build, they can learn construction also.

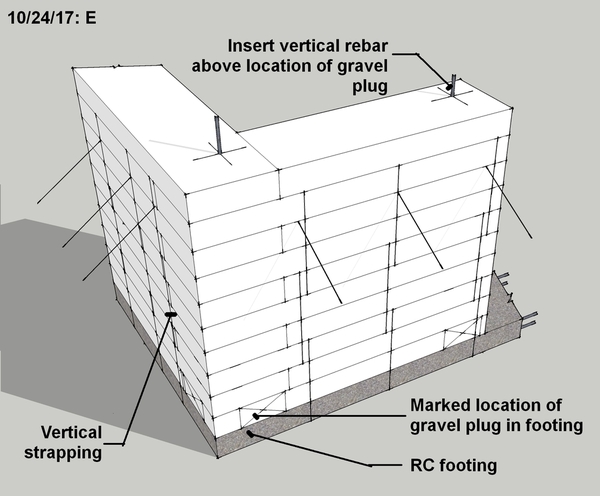

One of the weakest parts of earthbag built in risky areas is the lack of connection between a footing and the inserted rebar. Tests of wall shear strength show that inserting rebar bonds well with strong earthen fill. But can inserted rebar be bonded well to a footing to prevent wall racking? Students directed by an engineering professor known for practical hands on education will find out next spring.

Engineering students at Santa Clara University have been working with Patti Stouter for several months to plan for structural tests of contained earth (earthbag built with strong cohesive soil and reinforcement). Volunteers can learn about good construction techniques while helping to build these full scale walls during December 11- 15th.

Student teams will build walls, plaster them and let them dry for several months. Patti Stouter will be helping with the sample construction. If we have several extra volunteers, she can give seminars on choosing soils, reinforcement techniques and designing plans for earthen buildings in seismic risk regions.

Please contact Patti at pstouter@buildsimple.org if you can help!

I’m interested in studies of the affects of fires of any kind upon the polypropylene earth bags when they have been used in home construction. I understand that it has low resistance to heat.

Yes, polypropylene will disintegrate if burned. That is one of the reasons why it must be protected from fire or intense heat with a thick plaster. I am not aware of any studies regarding this.

I pounded metre length metal road-ties through my first 2 layers of hyperadobe earth bag and into the 3 foot gravel bag foundation to try to provide a more stable connection. I’m building in the UK, so not much chance of earthquakes, but it is on a slight hill, so I thought it wouldn’t hurt. I also pounded road ties from the top layer through the wood joist plates. Also used strapping.

Images won’t show up unless they’re already online.

Are they looking at like plastic geomesh or the basalt mesh that could placed within the footer at the time of the footer pour and as the wall was being build either the plastic or basalt mesh tied in between layers and the the mesh being part of the pour for the bond beam?

That would to me a way of having the wall to move as one unit?

I know Patti has been exploring many options. The students may only be testing the most promising idea(s).

Here is her description of how this system works:

They are using small sandbags where rebar will be hammered into the wall. After the rebar is inserted, they remove the sand and pack concrete around the overlapping rebar. This may increase strength by 50%.