“How much reinforcement do straight wall earthbag buildings need for earthquakes?

Engineers can’t tell without test results. Until this year no one has tested earthbag on a shake table, since full-size testing could cost between $10,000 and $15,000 USD.

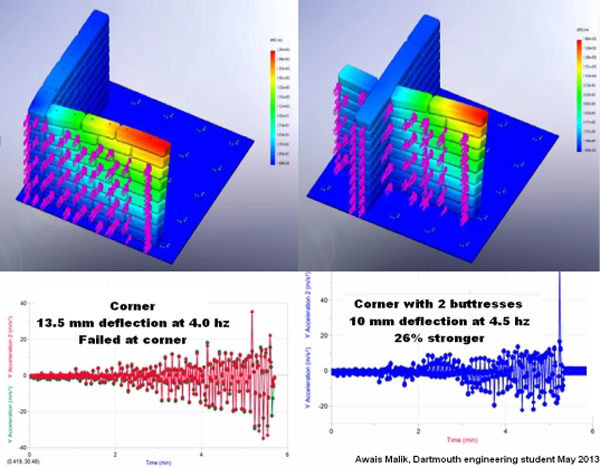

Dartmouth Professor Vicki May encouraged her students to examine earthbag after meeting BSI’s Patti Stouter at the $300 House Contest Workshop. Patti gave a skype lecture, returned to train students in earthbag technique, and acted as mentor for interested engineering students. Awais Malik dedicated 6 weeks to sew small bags, twist custom barbed wire, and plaster the corners of 1/6 scale models of 3 kinds of corners. Despite difficulties with outputs he was able to use the results of the shake test to create a computer simulation accurate to within 1.5%. Engineers use computer programs that simulate the violent stresses earthquakes cause to buildings, to learn without destruction.

Mr. Malik’s testing showed that 2 narrow corner buttresses or one massive thickened corner pier reduce earthbag wall motion under vibration by 26% and 33% respectively. The massive pier allowed the model to withstand higher frequency shaking, even though it was not well interconnected by the barbed wire. Under testing the square corner material fell out but the wall itself was not damaged at the corner. More testing is needed!

Engineers may also be interested in Malik’s finding of Young’s modulus of elasticity as 2.0 x 107 Pa, or in his description of creating the Solidworks simulation. More information is online in his thesis, Structural Analysis of Earth-Bag Systems.

Build Simple Inc wishes Awais well in his continuing studies, and would love to help with other plans for engineering tests!

Patti Stouter, Build Simple Inc.

Earthbag foundations were tested on a shake table back in 2009 for PAKSBAB.

Awais did pretty good running bond on his small scale project. Yes, bond beams would have helped, but the shake table could hold limited weight. I’m hoping another student might take it farther this year.

We have more hints than usable data from his project. We’d need larger scale test walls to compare to small, made out of the same soil.

We’re started. The questions are:

1- Is normal earthbag similar to adobe or stronger? I’m starting to see similar or a little stronger than unreinforced adobe. It’s an earth material, it’s not a lot stronger.

The old info about strong soil is very important! And always use more walls than openings for a heavy masonry building. Stability is what keeps low-strength earthen buildings strong.

2- Does earthbag resist earthquakes better or the same as adobe? So far damaged earthbag test walls don’t fall down, that’s much better than adobe regarding loss of life in quakes. But in vibration, will earthbag walls shake internally and not fracture- a cyclic shear test could tell that without a huge shake table test. I hope to find a university to help with this soon.

3- Exactly how much do different reinforcements help? This will take a while.

Many tests are needed. If engineers get excited about this, we’ll see a leap of knowledge.

I hope to make full-scale and 40% size walls in shear tests of the same soil to compare. And at least one shake or dynamic shear test of the same soil

As a 501(c)3 organization, Build Simple Inc in Placitas, NM can use cash or equipment donations and volunteer hours. I may stop testing when earthbag has been defined better. But we have a lot of tests needed before that will happen.

Patti:

I suggest what is needed is for an independent organization dedicated to building with Natural Matierials to build a shake table specifically to test earthbags as well as other technologies.

Perhaps an organization such as Aprovecho, DCAT, or some other educational organization dedicated to Alternative and Natural building might be a good place? Ideally the organization that builds something like this would be open to testing a wide variety of materials, such as Earthbag, Strawbale, Cob, Ferrocement, Papercrete, Rammed Earth, Rammed Tires, etc. Hopefully they also would be willing to invite the best experts from the various types of construction to come and participate so that the best techniques for each type of construction can be used in the test samples.

The shake table itself can be built with a big steel frame, old car tires to use as pneumatic bladders, some pneumatic valves and some big air compressors. This type of shake table has been built before for a TV Show.

http://dsc.discovery.com/tv-shows/mythbusters/videos/the-buster-awards-earthquake-shake-table.htm

http://www.youtube.com/watch?v=u7AMIPKeTGo

The Natural and Alternative building community needs it’s own testing and research, because we all know that it’s extremely difficult to get on the research agenda when all the corporate interests are the ones that fund most major universities.

Heck, I would even donate to a kickstarter for just such a project, if it was being done by an organization that I thought could be trusted to use the money wisely and conduct fair testing of Alternative and Natural building methods.

Such a testing center could be used by any number of students from various universities around the world.

While they are at it… might as well build an air cannon to fire 2×4 storm debris projectiles at walls built from various Alternative and Natural materials.

Create a full featured testing center.

Imagine what might happen over time if hard engineering data were available for every Alternative and Natural building system, and all their derivations, including all the different plaster and stucco techniques. How much strength does wire mesh embedded in stucco add? How much strength is added by a reinforced concrete bond beam vs a wood bond beam? What if earthbags are filled with Scoria instead of Earth or Sand? Strapping? Ideal Buttress spacing and size in various conditions? The list goes on and on.

Seriously…I bet building this test equipment could be funded through crowd sourcing… AS LONG AS AVERAGE PEOPLE TRUST THE ORGANIZATION DOING IT. People donating what they can afford whether it be $5, $5000, or $50,000.

With the right people doing it… this is very doable. In my opinion, it’s both the only way to get the vast majority of most of this testing done, but it’s the only way to get it done without corporations or politicians corrupting the process.

Sorry to take so long to reply. Yes, cohesive soil was used in the bags, and they were overlapped mostly pretty well. Test walls have to be a size that allows overlaps…

Awais had trouble with the accelerometer output, so it’s not the most accurate test. Motion sensors would be better next time.

My wish list for another shake test:

strapping between layers (very important for strength!)

weaving barbed wire out the corners and back in the next layer

bond beam

A full scale shear wall of the same material, and compressive strength and particle size testing of the same soil

But if we just get a dynamic shear test of a 60- 100% size wall I’ll be thrilled.

It only requires 2 hydraulic jacks pushing and pulling in a coordinated way and is much less expensive than a shake table to set up.

I’d also like to test one with sandbag base and one without.

If you know any engineers or professors email me at simple_earth@yahoo.com and I’ll send you my latest request for testing help paper…Forward it to them with a personal request to have them contact me about anyone they know who might be interested.

Hi everyone

Lots of great comments! I should have given more info about Awais’ technique.

Yes it was a good cohesive soil. FINALLY NO SAND!

And no bond beam- although you’re right that would have helped!

The stub ends need to be anchored to simulate the stability of the rest of the building.

Anyone wants to make or let us use a bigger shake table, please let me know! Even a dynamic shear test would be helpful, and uses simpler equipment!

The fact that Awais got his computer simulation to copy the models means that if he shares this with someone else, they’ll be closer to being able to predict performance of a real building.

So many things can change the strength. The walls seem like a very strong design. I wondered about the cone style tops, strength. I think a garden style roof that is insulated and tied down very well with little over hang would make me sleep better in an earth quake zone.

I guess an engineer could figure out strengths and weakness of different structures. It would be tough to do though.

Sand bag walls do give you a bullet proof structure if two rows or more are used. The strength of the base, footing. And the walls thickness are another variable.

I see the big round bales of hay/alfalfa and imagine how stable such a bale used would be in an structure.

We’re very grateful for the work Awais Malik has done. Lots of testing is needed and projects like this move things ahead bit by bit.

Patti has a Powerpoint presentation about the study, but not the actual paper with the detailed data, but that’s fine with me.

http://buildsimple.org/resources/AwaisMalik_Final%20Thesis.pdf

I don’t see a bond beam in any photo, unless he did a bond beam inside a bag top layer of reinforced concrete, but it doesn’t look like it to me in those photos.

I see a lot of holes in the study methodology, but it’s a good to have someone making an attempt. It has to start somewhere.

Pretty dang ugly walls if you ask me. He commented about how difficult it was to make 1/6th scale earthbag walls to put on the small shake table he had available. (100lb max capacity.) I feel his pain. It’s usually a lot more difficult to miniaturize something like this. Good to see him man up and put all his problems out there for everyone to see. That’s the right way to do it. Others that follow him can learn from his difficulties.

I kinda wonder if he could have spent less time by building a bigger shake table so he could go full scale. A shake table isn’t exactly difficult to build. It’s all the instrumentation to take accurate measurements that’s the difficult part.

It says his bags were 20MPa. There’s no freekin’ way that could have been sand. I’ve seen a lot of concrete get poured that was a lot worse than 20MPa.

I hope he will continue with more testing, and perhaps inspire others to take up the challenge.

It’s an imperfect study…(no study is ever perfect anyway), but it’s a beginning. Now it’s time to learn from it to improve for the next study.

Virtual pat on the back to Patti for her role in helping make this happen.

From your text in this blog post, Owen:

“Patti gave a skype lecture, returned to train students in earthbag technique, and acted as mentor for interested engineering students. Awais Malik dedicated 6 weeks to sew small bags, twist custom barbed wire, and plaster the corners of 1/6 scale models of 3 kinds of corners. “

Seems to me that if Patti lectured, trained, and mentored these students conducting the testing, that they probably used good practices in building the test walls. Therefore I doubt they used sand. She’s more than smart enough to discourage then from attempting that.

Also, it seems that they twisted their own custom 1/6th scale barbed wire. That’s probably the only way to get 1/6th scale barbed wire. Barbed wire isn’t particularly difficult to make. It’s just tedious and time consuming to make manually if you don’t have one of these:

http://www.youtube.com/watch?v=N9xuXWA-Orc

Thanks Owen. You said what I couldn’t find the right words to say. I thought that would be a more sound wall if you did it that way. Like you said…brick walls.

Looking only at the graphic posted in this blog post, I don’t see an upper bond beam on the top of the walls. Such a beam would dramatically strengthen the entire system.

I’d also like to see the impact that strapping from a bond beam to the foundation would have.

Then there is the added strength of possible roof vigas, purlins, etc helping distribute some of those loads.

All of these would improve performance.

However, doors and windows will tend to weaken the structure. Testing of various methods of connecting door and window bucks and/or lintels and/or arches seems an appropriate area of testing as well. It would be great to data in respect to all of those construction details. Come up with a best practices for the strongest structures in seismic areas backed up by testing and hard data.

Perhaps it is my nerdy tendencies, but I find this type of information the most interesting and fun. I want to read the actual report. Do you have a link to it online?

Yes, having a bond beam is very important. That one thing alone changes everything. I would also want to know what type of fill material they used. Sand would perform very poorly in comparison to tamped clayey soil such as road base or subsoil. What did they use for 1/6 scale barbed wire? Pinning? There are lots of unknowns.

The report is on Patti’s website. (link is fixed)

One question. Are the walls “weaved” together? one coarse runs through the intersecting space and the other coarse running through the other coarse. Back and forth so to speak. I hope you follow what I’m trying to explain.

The bags should be stacked in a running bond where each course overlaps the previous course like in brick walls. This includes overlapping the corners.

It’s interesting how these tests validate what we have learned about earthbag construction, how buttresses at the corners and spaced out along straight walls are important in earthquake-prone zones.

Yes, but we’re not sure how they built the scale model. The tests will not be definitive if the model didn’t simulate actual earthbag wall building methods. Hopefully Patti can fill in the details.

Good information.