The greatest need for housing in Nepal is in poor rural villages. Not only can they not afford cement and steel, it’s not practical to carry these heavy materials 1-2 days over mountain passes. We need to identify the most practical low cost earthbag building methods and create a document showing best practices.

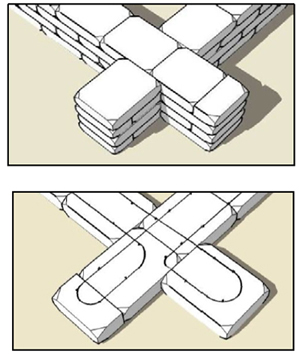

Everyone here really likes buttressed earthbag corners that extend in each direction. This method adds a lot of strength at not much extra cost. One good option is to build the buttresses half height so families can add additional rooms later. The future wall would connect to the buttresses with rebar and barbed wire.

Other highly promising earthbag reinforcement methods include:

– use the strongest building shape (in order of preference = round, square, rectangular);

– build small to save money and make stronger buildings (you can always add on later);

– good quality woven polypropylene rice bags or sand bags or tubes (make one earthbag as a test and see if the bag will burst after 5 minutes of hard tamping);

– double bagged gravel bag foundations on rubble trench to absorb shocks (round gravel is better than crushed);

– build on rocky ground whenever possible (reduces foundation costs and vibrates less than soft soil in earthquakes);

– dig a trench to divert water away from buildings;

– solidly tamped moist subsoil in earthbags becomes very similar to rammed earth in bags (ancient rammed earth buildings have lasted centuries through many earthquakes);

– one story earthbag walls 8’ high or less (use lightweight framing such as wood or bamboo if you want a second story);

– optional partial height earthbag wall to help block landslides (double earthbag wall on uphill side in higher risk areas);

– vertical 1/4″ poly rope strapping that goes around the whole wall including bond beam;

– nylon fishnet tied to the rope strapping plus nailed to the bags (lasts much longer than chicken mesh that would quickly rust);

– two strands strong barbed wire between all courses secured with recycled nails;

– some steel rebar pinning at key locations (doors, windows, corners, long walls) to stiffen walls and help secure the timber bond beam;

– earthbag benches next to doors (the weakest point in a house) with barbed wire connecting the bench and wall;

– earthbag buttresses in the center of long walls;

– small or medium sized windows or doors (minimum 1 meter from corners);

– good workmanship (straight, plumb, level, overlap joints in running bond like masonry);

– easy to repair earth plaster with good sized roof overhangs to block rain;

– lower part of exterior walls may use cement plaster to better protect against blowing rain and snow;

– timber bond beams with overlapped corners made with locally available wood (possibly cut flat on two sides with an adze);

– lightweight wood or bamboo roof framing plus free metal roofing from the government.

Image source: Drawing by Patti Stouter Build Simple.org