Announcing a new open source project at Natural Building Blog with free plans available after completion of design. Please submit your suggestions below for an ultra low-cost, disaster resistant earthbag home for coastal areas that are vulnerable to hurricanes/cyclones and flooding.

Millions of people who live along shorelines in developing countries are highly vulnerable to hurricanes and tsunamis. Coastlines in India, Indonesia, Malaysia, Bangladesh, Philippines and Vietnam are particularly vulnerable.

The coastal population of South Asia and Southeast Asia is approximately 350 million. In addition, there are hundreds of millions of people living in coastal areas in Latin America, Caribbean and the US that could benefit from this project. These figures are expected to double by 2025. Also note, drowning is by far the leading cause of child death in many Asian countries, and millions are made homeless in just one cyclone.

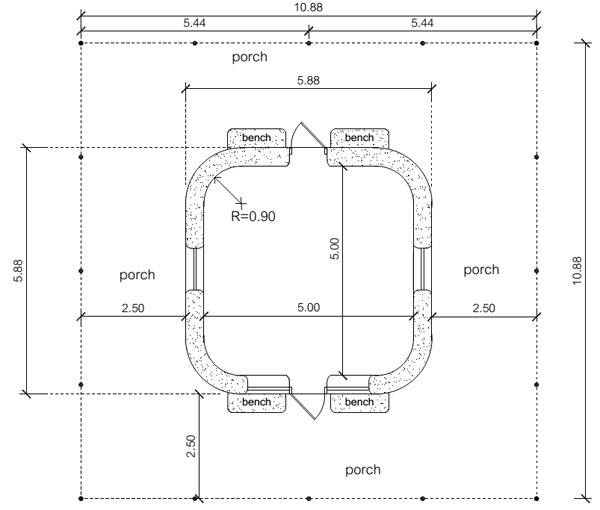

The goal of this project is to develop a basic 25 sq.m (270 sq.ft or about 16’x16’ interior) earthbag house with rounded corners for stability, wind resistance and ease of construction. Other recommended features include an insulated filler slab flat roof (popular for drying crops and sleeping at night), roofwater collection, vents high in the wall, earthbag benches each side of door, and small tilt-up windows (wood or plexiglass) that block blowing rain and work as storm shutters.

For the earthbag walls, I recommend hyperadobe raschel tubes with specifications from Bag Supplies Canada, rebar pinning, gravel filled polypropylene tubes on lower courses, cement/ cement with lime plaster.

The drawings above are preliminary. We want feedback from readers, NGOs, architects and engineers, and anyone else who would like to help. After the feedback period, the plans will edited as necessary and the final result posted here on our blog.

Questions to resolve include: Make one open living space with curtains or room dividers for privacy? Roof details? Size and location of windows? Size and number of covered porches for outdoor work areas? Build single or multiple units? How to fund a prototype or model home?

Previous related projects:

Post-tsunami Bamboo House

Post-tsunami Affordable Housing Project

Earthbag building guidelines for developing countries

From Bag Supplies Canada: The mesh tubing comes on a roll of 3,000 feet and is 14” wide and can be stretched to 20” wide when pulled. It comes on a bale that is roughly 33x33x17 and weighs 53 lbs so one can be shipped or even 2 that can be carried. We sell it for $337 CAD plus shipping and taxes.

For what ever reason this house brought to mind a Dogtrot house. While I’m not sure of the areas that you are specifically targeting with this, some of the other areas you mention like the caribean can be warmer. In areas with little power this could be a cheap and effecient cooling method.

The areas for these homes will be hot and humid like the southeastern US where dogtrot houses were built. Breezeways could be built between the houses. One option is to join two houses with a common wall to save materials and labor and build breezeways between the next two units on either side.

You might be able to cheaply and easily get both packing peanuts or polystyrene bean bag filler. Polypropylene also has insulative properties. It’s also used at times in reinforced concrete. I wonder if shredding a bag of that material would be viable.

Insulation for the roof.. I don’t recall the exact name but is that lightweight concrete made of styrafoam as the agregate. Glass is also insulative as an agregate as I understand and stronger as well.

Options include using an air entrainment foaming agent in the concrete, recycled shredded foam, panels of new or recycled foam, expanded aggregates… A lot depends on what’s low cost and readily available.

If you’re making an arched roof with a form, you could insulate by making the form semi-removable. After you’ve got your roof, drop the form by 8″ or so, then stuff with straw, styrofoam waste, whatever.

Forms may not be needed. Right now I’m leaning toward a series of shallow arches made of ferrocement with the slab on top. Still not sure exactly how to insulate it.

But then I felt one of the reasons for the roof likely that. I just thought it might be worth saying outloud.

I’m more orless suggesting when you do your mock up you do a mock up with those features. Show the over all potential. You mention using breakable or sacraficial material and with some of the locations bamboo came to mind. I also wonder if perhaps there could be a best of both worlds aproach for the flat foor and nubian vault Something similar to the earthship vaulted roof system. Vault, filler, then flat roof. That of course without being to complex or adding to much to cost.

Owen,

A few points on the house I built that might apply. On the rebar cages that run horizontally through the wall at mid level a half inch rebar is driven all the way to the ground in about 3 places and tied into the cage. On the bond beam to tie the vigas into the wall I first installed the cage with no support. Just laying on top of the wall. I then drilled two half inch holes through the 6×6 inch beams, one vertical, one 20 degrees and then drove half inch rebar through the beams, cage and about 18 inches into the bags. Where the rebar crossed just below the beam I tie wired it together and then used the rebar going into the beams to tie the cage to it’s proper height and then of course drove rebar into every bag that didn’t receive one while installing the beams. Formed it up and then concreted it. If my roof were to blow off that would probably be my smallest problem. One thing that amazed me about this technique (not mine by the way) was I was very concerned about the beams holding their position until everything was concreted. I was amazed to discover that once the rebar was tie wired together I could climb my 200 pound fat backside on the beam and it wouldn’t budge.

That’s solid, wow. Thanks for the details. I hope other people try out this method.

Filler slab roofs are popular in the area:

http://sepindia.org/ihd-sep/ceeef-technologies/filler-slab-technology/

A series of shallow arches like this would work. Pour the slab on top. http://lh3.ggpht.com/_sd4aOA0Ur-I/SgF1KFmJNeI/AAAAAAAAFew/IR4f1UzBhxQ/s1600-h/L%20-%20Eduardo%20Torroja,%20Zarzuela%20Hippodrome%5B5%5D.jpg

Raschel mesh tubes for a house this size would be around $75 to $100, depending if they’re bought in bulk or not.

Search our blog for raschel mesh or hyperadobe. Plaster bonds to this perfectly.

Something like this could be built for around $1,000 in materials. This assumes good soil nearby, mesh tubes purchased by the container load, etc. to keep costs as low as possible.

If a government agency or NGO can pay my way, I’m willing to train the workers and oversee the first prototype structures. My email is at the top of the page.

Also note, this is a simple house plan that’s primarily designed to show key concepts. Each city/area will likely modify the design so the houses are unique.

I also suggest considering a modular design. I wish could find the house but anyway one of the rooms was a tornado shelter. Basically if something hit that part of the house would be left and it had everything needed, bathroom and kitchen. You could throw beds in the dining room. Some way the home can easily be expanded. I also question if a ferrocement nubian style vault roof would be cyclone safe. I wonder if perhaps that could done at similar or cheaper cost. There’s the potential for more room.

This design is modular in the sense that it provides a core dwelling that’s disaster resistant. For adding on extra rooms, the porches could be enclosed. The outer rooms could be made very strong or they could use sacrificial lighter materials and the inhabitants retreat to the core dwelling during disasters.

Flat roofs are very popular in the region. Typical Nubian vaults are way less common than flat roofs. However, they do provide valuable loft space and are strong and disaster resistant… so they are an option.

You may have hit on a possible roof solution: The roof could be formed into a low arch/low Nubian vault (18″ high?) with steel and mesh and the slab poured on top so the roof is flat. Done correctly, this could be stronger than a flat roof. It would need to be insulated. Thank you for this suggestion.

Consider using a hexagonal wall design instead of a square or rectangular one. A hexagonal structure if much stronger.

Most people in this region want square or rectangular designs. The design must be accepted by locals for it to be successful.

One question the arises when I look at the plan: How do people access the slab roof?

This is something that has to be worked out. There could be a ladder on the side of the house and a hatch door.

You should use the sensibility of tiny houses basically. Consider something like this http://www.fourlightshouses.com/products/washroom

If you can work in a loft there this

http://www.fourlightshouses.com/collections/component-furnishings/products/tansu-stairs

There’s alot of building methods as this blog makes clear but theres not alot of people working together mutually. You have all of these independent groups doing there own thing. If there was someway to better bridge the gap, if just consulting. The Earthship crew went to Haiti. They found there qwas little need to build a kitchen there. They let that completely go. However the rock method of cooking poses a humanitarian issue as well. There are people spreading rocket stoves there. One woman they found 3 weeks later had not used her for fear animals would knock it over and start a fire. They did these elevated built in rocket stove counter thing and even ended up adding an oven. I wonder what could have been done if these two groups had worked together. For this project I would say consult with people in the tiny house movement. The average cost of a tiny house I’ve read is $30,000. Withy earthbags I wonder how far that goes down.