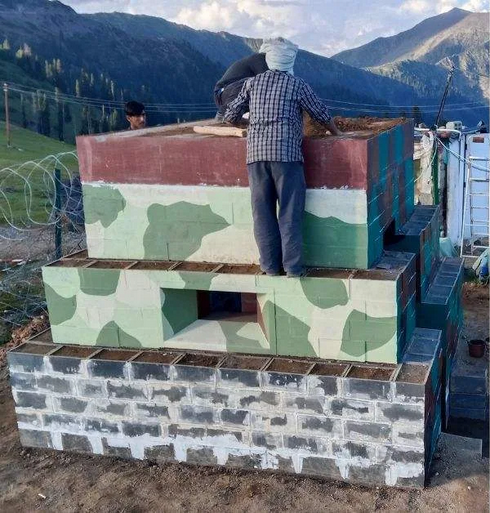

At 14,000 ft in Kashmir, India, where the winds and weather are harsh, there’s a bunker inspired by traditional sandbag construction. Designed by R+D Studio, the material is Silica Composite Hollow Blocks, which are made up of 80 percent foundry dust and 20 percent plastic waste. The bunker was assembled in just three days, with its layered walls engineered to withstand 25 feet of snowfall.

The walls are strengthened with compacted earth, which insulates the interiors and makes the structure impenetrable. The architects say that this will set a precedent for future sustainable projects where natural resources such as soil or water can be eliminated in the production of building materials and ‘waste’ can form the core of a structure.

The walls are strengthened with compacted earth, which insulates the interiors and makes the structure impenetrable. The architects say that this will set a precedent for future sustainable projects where natural resources such as soil or water can be eliminated in the production of building materials and ‘waste’ can form the core of a structure.

The material can be molded into any shape and exhibits 2.5 times the strength of traditional clay bricks. The project harnesses materials that are otherwise considered waste. This is probably one of the few materials that is 100 percent sustainable; made with 100 percent recycled material. Silica dust is the waste of the casting industry, the binder is made of single-use and multi-layered plastic (the plastic bags that you commonly see) that usually get discarded in our in landfills.

The material can be molded into any shape and exhibits 2.5 times the strength of traditional clay bricks. The project harnesses materials that are otherwise considered waste. This is probably one of the few materials that is 100 percent sustainable; made with 100 percent recycled material. Silica dust is the waste of the casting industry, the binder is made of single-use and multi-layered plastic (the plastic bags that you commonly see) that usually get discarded in our in landfills.

Once the use of the material is finished, it can be recycled back in the factory for a new use without compromising its strength, which is comparable to metal. The material is 20 times stronger than concrete.

Once the use of the material is finished, it can be recycled back in the factory for a new use without compromising its strength, which is comparable to metal. The material is 20 times stronger than concrete.

You can read the original article at thebetterindia.com

You can read the original article at thebetterindia.com