“Hello, We want to add two rooms to an existing small older home, my question is: We want to build a straw bale home with pallets on both sides, the thought is to put up the straw bales, then put on earth/clay/mud on the bales. As we put the mud on we will put a pallet up against the mud on each side and finish the wall, then once the mud is dry put adobe mud with straw [straw/clay] inside the pallets. This would create a very thick insulated wall. We live in North Dakota where it gets very cold and windy. Maybe we could put a somewhat flat roof so that it can be an earth roof with herbs. We will recycle rain water. Has anyone built walls in this manner? The room would be about 20ftx12ft Would this be sturdy enough to hold two story? There would be a partition wall in the center. We want to build being considerate of the environment and have little money. The pallets we are collecting free of charge just gas to pick them up. We would make our own mud/adobe and can get straw inexpensive, otherwise we will not be able to add on. We appreciate all the help you can give us as our funds are limited and work up here in the North is very little in the winter months and pay is not so good either.”

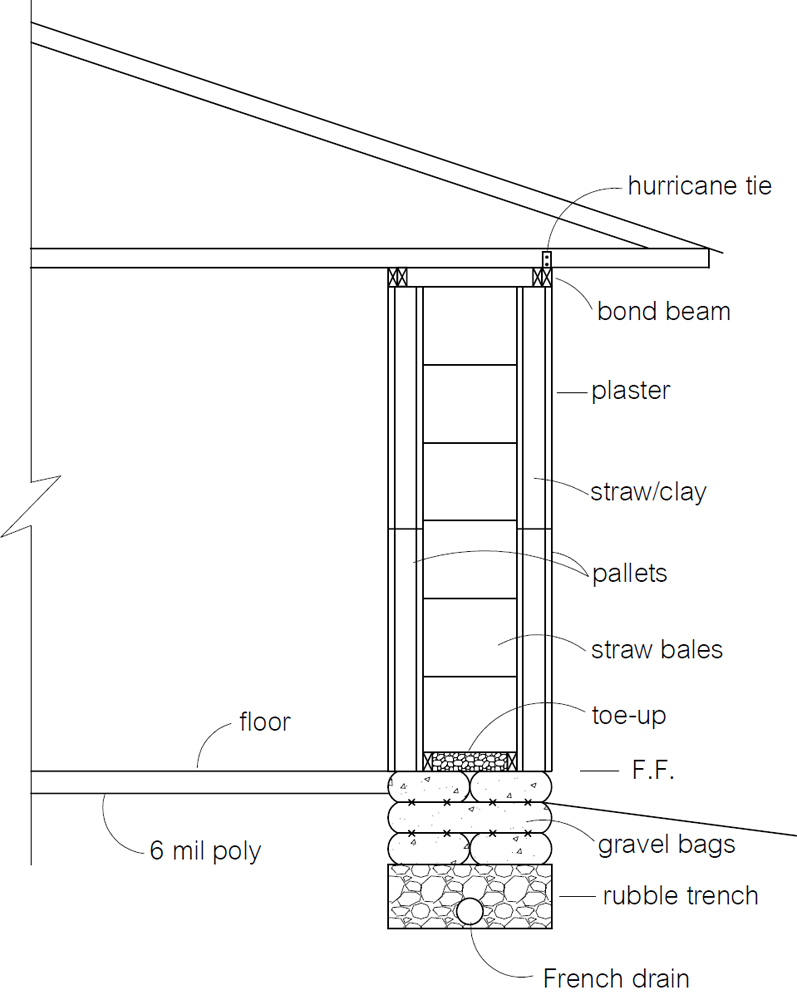

Owen: I like your idea very much. A straw bale/pallet wall will work for your purpose. One suggestion is to lay lengths of baling twine between the bales as you stack them and then later tie to the pallets. This will add a lot of strength. Be sure to raise the bales well off the ground away from snow and rain on gravel filled earthbags. And you’ll want to build a bond beam along the top of the wall to tie the whole structure together. If you do everything correctly, then I believe a 2nd story is possible, but only with careful workmanship and working out the details.

Key points:

– It’s way faster and easier to use earthbags filled with gravel instead of tires.

– Brick on the outside is possible, but will greatly add to the cost unless it’s recycled.

– Typical living roofs are very heavy. Research thin, lightweight living roofs.

– Do not use a moisture barrier on the walls. Vapor must be able to pass through the wall.

– Build a strong bond beam as shown in the drawing and then you can add a second story. Insulate the cavity in the bond beam.

– Papercrete is prone to molding, especially in damp, cool climates. Do not use in your area.

– Add plaster mesh or chicken wire to the pallets, and plaster the walls. Wood siding is another option.

– Rainy areas create risk of the walls getting wet during construction. I suggest building a post and beam structure (pole building) first, then the roof and then the walls.

I would like to insulate my garage which I use as a store room with straw bales.

Is anyone there who can give me a quote and do the work?

This is very simple work. The best approach is to learn what needs to be done and then hire local workers to do the more difficult work like electrical, plaster, etc. You probably won’t find a contractor to do everything for you unless you live in an area like Santa Fe, etc. where building with bales is popular. But you don’t need one. Read Matts Myhrman’s free strawbale ebook that’s linked on our blog (search his name to find the story). His book explains almost everything for free.

I’ve been looking into interior pallet walls as well. I keep getting hung up on what to use to finish the walls other than drywall etc. Any ideas??

My blog on this topic is coming soon. Most use earth plaster, but you can also use wood boards, plywood, stone…

The question was asked if pallets could be used on interior walls?

We are using pallets for the division between the room, one side of the room will be for a bed the other side of the room will be like a sitting room/hid-abed if needed the division will have pallets side by side to help support the heavy earth roof the we will build book shelves on each side of the pallets so the pallets will be hidden and we will not have to do anything else with them.

We will also use pallets on the interior wall between garage and kitchen addition this will help to support the upstairs bonus room.

At least this is the plan for now, we are in the planing stages and will start this spring as soon as weather permits.

Marie

Pallet walls are a top choice in my opinion. This type of construction is really start to catch on.

I am planing to put either loose straw or newspaper between the ceiling and roof for insulation, have already spoken to the local newspaper owner and she will give me all the newspaper I want, I was going to make papercrete adobe mud to put in between the pallet for insulation but was advised not to do papercrete since it is so humid here in ND, we will go with straw between the pallets, we will also have strong posts in each corner of the room.

Our goal is to add a large 20/12 room to the North side of the house and a two car garage extending the existing small kitchen into the garage addition with a bedroom upstairs above the garage/kitchen addition, this house is small and older, and the addition would be handy but we cannot do it the conventional way and in all practicality we want it to be totally environmentally friendly.

The large bails in which we have here are great for building but the walls would be way too thick for the house part of it, although we have talked about using large bails to build a bungalow in the back for company using large bails and covering it up with lots of dirt roof facing the South sun, it is a long term project, one step at a time.

Thank you for all your help

Marie

Loose straw and newspaper in the attic is an extreme fire hazard. One very good option is cellulose insulation that has good fire resistance and high insulation value.

You’ll probably need more posts than just the corners. It’s a good idea to put a post every 8′-10′. Let’s say the pallets are about 3′ wide and so you could put a post every 9′.

Use straw/clay inside the pallets. This is a mixture of straw mixed with thin liquid clay. Mix like a tossed salad and stuff in the pallets. This is a proven system with hundreds of years of success.

Interesting idea for economical wall construction, would still need load bearing supports somewhere in the wall with this system though. I would probably cut the interior pallets in half, placing the full size one in the middle. This would change the common joint created by stacking them on top of each, eliminating a potential weak point in the center of the wall. The interior pallet provides a perfect area for electrical and plumbing to go. Batt insulation could also be added because most pallets have fewer boards on the bottom than on the top. Place the top with more boards against the wall then slip the larger pieces of insulation right in.

Yeah, the upper row and lower row of pallets can ‘hinge’ in the middle like you say. That’s why people add vertical 2×4’s at the vertical joints. Slide the 2x4s down inside of the pallets or just nail to the outside edge between pallets. A nail gun would be real handy for this. This particular lady has decided to go post and beam so she can build underneath a roof out of the rain, so her structure will be much stronger than just pallets tied together.

this is interesting. I wonder if you could pack other lightweight materials between the pallets?

Right away I thought of mixing packaging peanuts in clay slurry. We’ve talked before about using these recycled styro peanuts on the Solar Pit House: http://earthbagbuilding.wordpress.com/2011/09/15/solar-pit-house-building-details/ I’ve known of the possibility of doing this for years, but a reader emailed me last year and said her previous job was disposing of shipping container loads of packing peanuts! That’s when I realized there’s a huge free resource that would be very easy to find in any city.

You could also mix scoria or pumice with clay, or clay with vetiver grass, etc. Lots of options.

yeah, i see lots of options, even loose fill straw or recycled styro…

Losoe straw is more of a fire risk, and would be more likely to attract pests. You don’t want dead mice in the walls. Straw/clay or light straw/clay made with a thin clay slurry is the perfect match. Styro/clay (I just made up this term) or just styro peanuts would work great.

yeah, there are lots of options. I grow oyster mushrooms, and the spent substrate is a mix of mycelium and straw. It is lightweight, and full of air pockets, and would make an excellent insulation material. In fact, you could grow the mushrooms right in a form, and when you’re done harvesting, drop the remaining block in your wall.

The danger with this is if you ever got moisture levels high enough, the substrate would start growing again!

In some areas you don’t need building permissions for “non-permanent” houses. I just wonder how it would be possible to build a small one-storied straw bale/pallet house which you could dismantle and move to another area…

One easy way is to call the structure an ‘out building’. This is a term used by building officials for storage sheds, animal pens, etc. These are very common on farms and skirt the building codes. Now, technically you’re not supposed to live in out buildings, but people do what they have to do.

It would be easy to move the structure if it’s never plastered — just cut the baling twine and load the pieces on a truck or trailer.

I wonder if pallets could be used similarly for interior walls (obviously not with straw bales – with something else in between?)

Shhh! That’s coming soon.

One idea i thought of is to use those big round bales ive seen in fields along the highway.Large and very thick. I considered digging four to six feet down so one or two bales stacked woud be high enough.The roof is a heat lose spot and i wondered if anyone had built a roof with bales between the roof and ceiling.

I saw a small vault style straw bale shack.The idea is appealing with bales covering the whole structure.Two storys? i guess im into smaller places,good luck.

Big bales are difficult to work with, take up too much space and require a large foundation. For most people they’re not practical. But I am working on a house design for a client who wants large rectangular bales. It makes sense in his situation once you understand his circumstances.