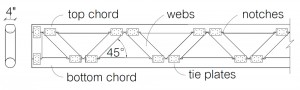

Inspired by projects such as William Castle’s house, featured on our blog yesterday, I set out to design an open web joist using small diameter poles for non-code areas. It’s not as shiny and elegant as manufactured brands, but hey, who can argue with the cost? These trusses would cost just a few dollars apiece if you have a good source of poles. In parts of the U.S., and probably other countries, the poles you would need are practically free. Small trees like this are thinned out to reduce fires and help larger trees reach marketable size. You could use scrap metal for tie plates and cut the cost in half. Barter for a can of screws and you’re talking really dirt cheap.

Benefits include:

– Utilizes abundant, low cost and rapidly renewable small diameter roundwood, which is inherently stronger than milled wood.

– DIY, owner-builder friendly with few tools required.

– Top and bottom chords could be replaced with milled lumber if desired to speed construction.

– Easy installation, although heavier than manufactured brands.

– Open web design allows easy installation and of plumbing, electrical and ductwork within the joist without drilling or notching.

– Can be used for floors, roofs and to create superinsulated walls.

Basic building process after the end grain has been coated, and the poles have been peeled and dried slowly under cover:

– Select straightest members for top and bottom cords. Trim off cracked ends and recoat ends again with recycled paint or varnish. Top cord is milled flat on the top, so this member could be slightly larger than the bottom chord.

– Crown the top chords and cut a flat surface on the top. This could be done with a chainsaw (probably fastest, easiest), power saw, power planer, bandsaw, jointer, etc. One method is to tack a 2×4 to the pole (with a slightly crown) and use it as a guide for a chainsaw. Note: I would leave a slight crown on the poles for added strength and because it will settle under weight.

– Use a radial arm saw with a dado head to cut notches about 5/8” (1.5cm) deep. With 4” poles, this will give you about 3” of bearing surface for the webs.

– Cut the webs to length with 45 degree ends.

– Nail or screw the webs in place. Screws will likely produce fewer floor squeaks.

– Use a grinder or other tool to flatten areas for tie plates. Nail or screw the tie plates on.

It helps to study the free online catalogs shown below to work out the details for various applications.

Image source: Accurate Roof Trusses

SpaceJoist

Posi-Strut