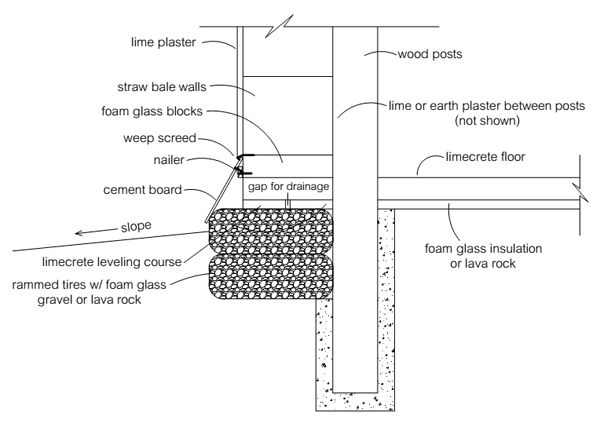

Yesterday’s blog post was about the foam glass insulation we plan to use on the Wiki Natural House. Today we’re giving a sneak peak (first draft) of the foundation design. The primary design considerations are low cost, owner-builder friendly, minimal cement, must withstand cold and wet climate (insulation is key), must align with thick straw bale walls and meet UK building codes. That’s a pretty tall order. Many of my designs are for rural areas with few or no codes. In this case, we have to put a little more effort into workable solutions.

>Wiki Natural House Proposal – free, open source, code approved straw bale house plans.

I’m sure that the foam glass is extremely strong as long as it is in uniform compression.

However, if the loads are not uniform, that can create a shear stress that many ceramics are not designed to handle.

In any case, it appears to be a moot point, since you just posted that the twine will go all the way down to the tires. This eliminates the stress points in the ToeUps from the strapping. That is a wise choice. It keeps the foam glass completely in compression and eliminates the potential of the problem.

Just for reference. Some readers may not be familiar with Ziggy’s initial floor in Gobcobatron, and the mold issues that he was forced to correct.

Here are a few key entries from Ziggy’s blog that give some of the details.

http://www.small-scale.net/yearofmud/2011/02/14/mold-has-reared-its-ugly-head-winter-moisture-issues/

http://www.small-scale.net/yearofmud/2011/02/18/update-mold-winter-moisture-issues/

http://www.small-scale.net/yearofmud/2011/08/30/replacing-and-insulating-an-earthen-floor-part-1/

Ziggy’s web site has been mentioned before on this blog, but I’ll take this opportunity to once again bring it to everyone’s attention. Ziggy does a great job of telling about his successes as well as his setbacks. Ziggy doesn’t have failures. His setbacks are merely learning experiences that shares with everyone so that you can learn from them too. The story about his floor, and the mold issues in his house are a perfect example of lessons that you can learn from his blog instead of repeating them yourself.

A few thoughts:

Please don’t take these items as an attempt to be overly critical. These are real concerns that I have, especially since you are trying to create a design standard that can be used most anywhere.

1. I don’t see anything in your drawing for weeping tile, or french drain. Accidental oversight?

2. No vapor barrier below grade is shown in the drawing. (See Ziggy’s nightmare from the first floor he built for Gobcobatron for what can easily happen by neglecting this. He later had to rip out his entire floor and install a vapor barrier and insulation to correct terrible mold problems.)

3. No drainage layer beneath the floor. This combined with the lack of a vapor barrier is asking for moisture problems. I recommend at least a layer of sand, or better yet, a layer of crushed gravel underneath the insulation.

4. I don’t see any pinning for the rammed tires in the drawing. Was this intentional?

5. While I see the post in your drawing, and I assume that the roof will be tied to a post and beam structure. Strapping is extremely cheap insurance that a walls remain in compression and it greatly reduces cracking in plaster over time. I don’t see any provision in the drawing for strapping. Also, walls see significant forces in winds and can flex a lot more if they are not strapped, this leads to even more cracking. Personally, I recommend strapping all strawbale walls.

6. It appears that you are using the foam glass to make ToeUps? ToeUps, regardless of what they are made from are best when firmly attached to the foundation. This ties the entire structure from roof rafters all the way down to footings as one structure, making it extremely wind resistant.

7. It’s usually best to include a vent pipe to below the floor (in the drainage layer I mentioned earlier) if Radon venting eventually becomes necessary. Perhaps this could be included as an “option” depending upon local soil conditions. Rule of thumb, if in doubt, put the vent pipe in. It’s extremely cheap and easy to do during initial construction and a lot more expensive, destructive, and a major pain in the butt to have to add the pipe later. Just because the vent pipe is installed doesn’t mean any expensive ventilator equipment needs to be installed unless post construction Radon test show it to be necessary.

8. If you are using the foam glass as ToeUps, it becomes necessary to think long and hard about how strapping underneath those ToeUps can create a concentrated force load on that ceramic material. I don’t know the strength numbers of Foam Glass, but it might tend to crack at the strapping and cause the strapping to loosen and fail. I would need more specs on the loads involved and the strength of the FoamGlass to calculate if the forces are approaching critical. In any case, this looks like a potential weak point that needs to have the numbers run to ground to be certain.

9. An alternative might be to run the strapping all the way under the tires. This would eliminate the stress points in the Foam Glass.

I applaud what you are attempting to accomplish. I hope you take these thoughts as an attempt to be helpful and not critical, because that is manner I am offering them. I wish you well on your design.

Thanks for the input. Not every detail is shown in this preliminary drawing. Strapping (probably baling twine) would be used to tie everything down to the tires. The foam block serves as a toe-up. It’s very strong and can surely handle the load. The roof load is carried by the post and beam frame. We’re also hoping to find an architect or someone in the UK who can provide specifics.