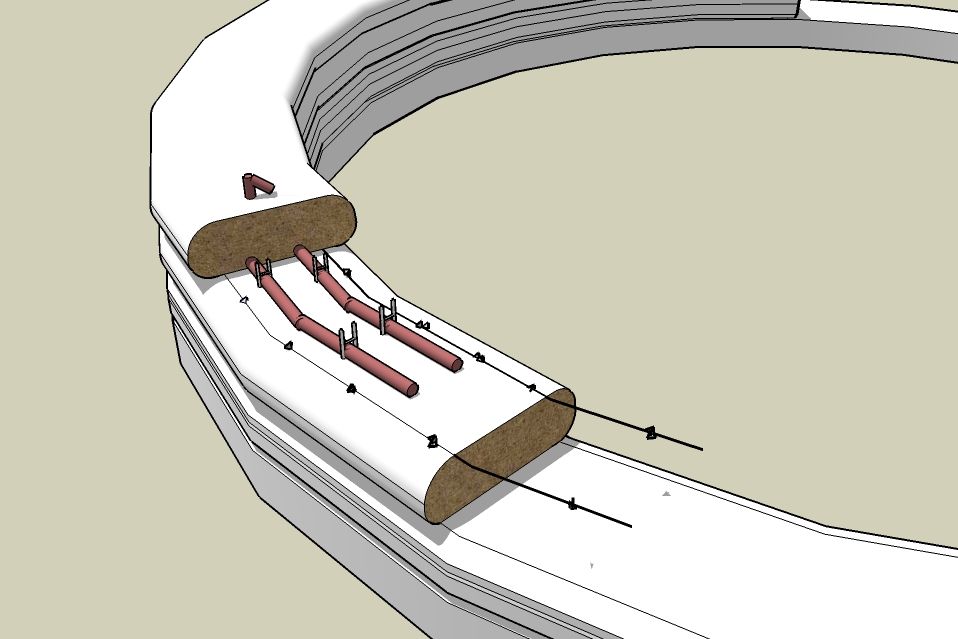

Forming bond beams for roundhouses and other curved structures is somewhat difficult. Here’s a brief description of an alternative bond beam that requires little or no formwork. It’s made with two layers of long poly tubes filled with stabilized soil (non-seismic zones) or concrete (seismic zones). Tubes could be filled 3″-4″ thick to save on cement. Put barbed wire and horizontal rebar (pinned in place) between the tubes as shown. Add vertical rebar to pin the bond beam to lower courses. Add lintels (or temporary supports if using concrete) over door and window openings. You could add strapping or wrap plaster mesh over the bond beam for added strength.

Note on fasteners for horizontal rebar: use H-shaped custom made fasteners with prongs that embed into bottom and top tubes.

Note on using concrete-filled tubes: you will need scaffolding/planks set up along the wall to pour the upper tube. Two sets of scaffolding could be leapfrogged.

Special thanks to Patti Stouter for the drawing.

This structural reinforcement of the circular rods I do not see much application, I would build a wedge of one meter in concrete, a base angle of 10 to 15 centimeters, 10 centimeters high with the upper vertex rounded, and in the three pieces of rod of 1/2 ″ base fused to the base and protruding 15 to 20 centimeters to be embedded in the center of the wall of the tube filled with stabilized earth, a hole is made, it is filled with a strong mixture in mortar and then the tips are embedded , and the pyramidal shape of the wedge fits into the next row of superadobe, they can be placed every 2 meters or 4 distributed around the contour of the circular wall every 2 or three rows.

Esa refuerzo estructural de las varillas circulas no le veo mucha aplicacion, le construiria una cuña de un metro en concreto, un angulo de base de 10 a 15 centimetros, alto 10 centimetros con el vertice superior redondeado, y en la tres pedazos de varrilla de 1/2″ base fundidos a la base y que sobresalgan 15 a 20 centimetros para ser encajados en el centro de la pared del tubo lleno de tierra estabilizada, se practica un orificio se llena de una mezcla fuerte en mortero y luego se encajan las puntas, y la forma piramidal de la cuña se encaja en la siguiente ilada de superadobo, se pueden colocar cada 2 metros o 4 repartidas en todo el contorno de la pared circular cada 2 o tres iladas.

Greetings!

I know this article is old, but I’m commenting here hoping someone is still keeping an eye on it.

I am in the stages of planning an earthbag roundhouse build that is 15m in diameter. Wall stability is an issue, but I really do not want to use buttresses if they can be avoided.

I was looking at the alternative bond beam for the top of roundhouse walls and it got me to thinking…

If I were to incorporated this rebar “locking ring” method into the entire build, staking down a double ring of rebar every four or five layers of bags, I would think this would negate any forces trying to push the walls outward and would result in a wall with significant internal support that would make buttresses unnecessary.

Is my thinking valid, or am I not thinking correctly about the physics involved?

Any feedback or advice will be greatly appreciated!

A circular earthbag structure does not generally require buttressing, as long as the door and window openings are well reinforced with vertical pins, especially if they are tied into the bond beam. What you described would certainly help make the structure more robust, but I doubt that it is necessary. The barbed wire really serves the same function.

Even if the structure is 15m in diameter? The article said that a 10m diameter circle was the max safe size structure without using buttresses or reinforced earthbag walls. This has me thinking that I need to add additional support to the walls.

The build I have in mind will have interior earthbag walls that will add stability to the exterior wall, and a central 3m wide circle in the middle of the house. It is also a two-story build, with the second-story wall being one-third earthbags and the upper two-thirds planned to be finished in something lighter. Floor beams will join the inner circle to the outer circle like spokes, and will also lay across a few interior walls adding to the stability of the overall structure.

Feedback from some other builders has me concerned that the 15m diameter may still pose some stability issues though, and I’m investigating options.

And thank you for the quick response! Glad to know this site is still active. A ton of helpful info here.

It is true that smaller cylindrical earthbag structures are inherently more sturdy than larger ones, but I still think that even at 15m diameter it will be plenty strong, especially with the additional support that you describe. Be sure to incorporate lots of vertical pins and attach the interior partitions well to the exterior earthbag wall. Using periodic alternative bond beams would give you additional confidence.

Thank you for the feedback. I needed to be sure I was on the right track in the way I’m thinking about things as we plan.

I understand the function of the bond beam. I’m confused specifically about the horizontal rebar within this particular “bond beam” scheme with two hyper-stabilized courses as I don’t see how it provides more strength than the vertical stakes. I’m trying to discern what its particular role is between those two bags and how it would be better than many vertical/45 degree stakes. In a poured concrete bond beam this piece would be important to keep the concrete from cracking but this scheme uses earthbags so I’m having trouble imagining it doing much more than what the barbed wire does.

The rebar is not in bond beams to keep it from cracking so much as the rebar prevents spreading forces (prevents top of wall spreading apart).

The stabilized tubes on top of the wall create a solid bearing surface for the roof members. They lack tensile strength to prevent spreading. Each part places a role in creating a strong building.

I guess I’m having trouble visualizing the function of it compared to the pounded lengths of rebar. I only want to do that if it is an improvement. I trust your opinion on the matter and will include it, but could you elaborate on its function compared to pounded stakes of rebar?

The vertical rebar keeps the bags from shifting. The bond beam keeps the top of the wall contained in a circle. Use both methods for strength. Bond beams are very important!

Thank you, Owen. This would be much more feasible for me than a poured concrete bond beam. My preliminary plan of action is as follows. I have two more bags (24″ cal-earth tubes) to lay until I am around my final desired height of 9′. I will hyper-stabilize these bags with 30-50% lime (I don’t know what number will be best yet). All my bags are stabilized with 5-10% lime.

I have a selection of metal hurricane straps that I can lay under the next bag and bend up 90 degrees on both sides of the wall. I have a large roll of 12.5 gauge 2 strand galvanized barbless wire. I can use this to attach the rafters to the hurricane straps under the bags. I also plan to drill a hole in each rafter and drive rebar vertically through the rafter into the bags below it.

Around the 6′ mark, I drove 2′ lengths of rebar 2′ apart all the way around my bags. Now at the 7.5′ mark I can do this again. And again after the last bag is laid.

Question, if I go overkill on driving vertical and angled rebar all the way around the next bags can I safely skip the horizontal ring of continuous rebar around the structure? It seems I would get more strength from this scheme.

No, you need the continuous horizontal rebar to tie the top together so it can’t spread apart. You’re already skipping a typical bond beam, so don’t cut any more corners.

Add strong galvanized wire or poly or nylon rope to tie down your roof framing. Loop it under several courses of bags so the roof can’t blow away. Add collar ties or rafter ties to prevent spreading of roof framing.

Okay, this is the guy who has been emailing you. I’m putting a roof on my structure I planned to be a dome. @9 ft high, I’ve stepped in 1.5ft of 7ft internal radius, however the last three bags are not stepped in, they are vertical. I want to attach a reciprocal roundwood frame to a bond beam via j bolts or similar and put a living roof on it. I’ve been brainstorming using an earthbag as a bond beam form and I stumbled across this post. It says to use stabilized soil if in seismic zone. I am not in seismic zone but do have in high wind/hurricane potential. In a typical bond beam where you build the form then pour you are left with a sharp outer edge where the angled rafters will sit. I’m concerned about that being the only point of contact with the rafter, would rather more surface area in contact. It seems to me using an earthbag as a form would create a more rounded surface on which the rafter would sit and so distribute more weight across a larger surface area. If I poured a formed bond beam I could come back and stuff an earthbag under each rafter to alleviate that issue.

This could work for you. Use continuous rebar all the way around if possible or minimize number of pieces. Overlap ends about 2′ and join with strong galvanized tie wire multiple times. Improvise pins that hold the rebar in place. Add loops of poly rope or strong galvanized wire under several courses of earthbags to hold down rafters. Drive some 1/2″ rebar pins down through the top 3′ of dome to help tie everything together. Add collar ties or rafter ties to prevent spreading (horizontal movement) of roof. If you use stabilized soil on the top course, add quite a bit of lime or cement to make sure it doesn’t compress.

I’m stabilizing with lime. Would that work for this idea?

Tell me more about what you’re doing. Alternative bond beams are for extremely low budget jobs (no codes, developing countries…).