Domes are vulnerable to water damage, so what to do in rainy climates? I say add a roof. There are various roofed dome houses on our main website at EarthbagBuilding.com that you peruse here and here. Those are earthbag domes. The design I’m first presenting here is made of ferrocement. It’s just one more way to do things.

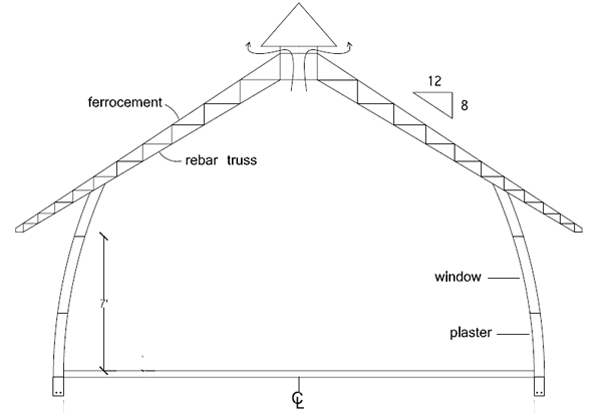

Ferrocement domes are prone to overheating because they’re exposed to direct sunlight, so I added a roof with good sized roof overhangs, a sloped ceiling with roof vent so hot air will naturally escape through the top, and exterior cladding of plastered low fired brick. A ½” gap between the ferrocement and brick helps prevent overheating and moisture problems from driving rain.

Basic building info:

– concrete foundation

– ferrocement shell (rebar, mesh and cement)

– rebar truss roof coated with mesh, cement and roof coating or possibly red clay tiles

– perlite insulation in truss

– low fired clay brick on exterior walls with rain screen (gap between brick and ferrocement)

– lots of arched doors and windows for good ventilation (round windows no problem)

– low fired brick or wood nonloadbearing partition walls are optional

– concrete or soil cement floor with iron oxide stain or tile with moisture barrier underneith

How much rain or snow or sleet do you think a Ferrocement Roofed Domes could hold up to? Sorry we are still trying to figure out the best roofing system for either a dome or round house in a teprate zone that gets 41 inches of percipitation a year. We want to avoid leaks as i’m sure every one does as much as posible. :) oh an good news we will this weekend going up to talk to parents to see if we need to get it deeded over now or if we want to wait. :)

They make boats out of ferrocement, so you can make it as waterproof as you want. This takes good skills, workmanship and maintenance.

I had an idea I call a ‘witches hat’ roof. Do an earthbag dome, insulate it however you feel like, but leave some attachment points protruding from the structure. Build a wrap around deck with a 4′ overhang. Starting from there, wrap a ring of metal roofing material (shingles or sheet, doesn’t matter),cover the top inch with something to let air thru that won’t wick up water. Overlap that material with the next layer up, repeat. Cap with acrylic dome, aluminum cone, something like that. Inspired by Owen’s Chum roof hobbit house design.

What supports the metal roofing?

Witches’ broomsticks, of course.

Attachment points (wooden posts, rebar, whatever) protrude from the structure. Use reasonably solid insulation that can support the roof weight resting on it (papercrete, hyper-wattle). Yes I’m half the same person, it just shows up differently when I’m on the desktop or the laptop.

yes…I like it!

Yeah, one vote. How’s your dome coming along? Any new videos?

Obviously this design has more embodied energy than say earthbags and adobes. Although ferrocement uses less steel and cement than typical concrete structures and therefore is an option for sustainable builders, it still uses a lot of energy intensive materials. Ferrocement is probably best reserved for specialty uses such as vaults and curved roofs. An entire house of ferrocement would not be my choice.

Interesting design.

If someone is considering building an entire structure such as this out of ferrocement, I would suggest considering the entire wall and roof structure as one big truss structure. Built a large jig to lay out all of the rebar pieces accurately and weld them together. Then remove and repeat.

A half jig would be sufficient. A jig that forms a truss that forms the rib of one gore complete with roof overhang, all the way down to the foundation.

Then simply weld two complete trusses to the center ring and tip it up verticle. Brace it plumb, and then add two more truss ribs 90deg askew. A creative truss connection design at the center ring where the rebar can hook into the center ring would be very helpful. That would help stabilize everything as it is getting erected and welded.

Here is another thought… completely thinking out of the box and off the cuff. I’ve never even attempted it in a model, let alone for real…

What about making trusses as I suggested, and linking them together the same way a reciprocal roof frame is formed at the center?

I find myself wondering if each arched reciprocal truss will want to stay in place or if it will want to flop over until everything gets braced. I don’t have those answers, so if anyone attempts it, please be careful and do your homework.

All that said, in my own humble personal opinion, an earthbag roundhouse makes a lot more sense.

It’s difficult or even impossible to get code approval for earthbag buildings in many areas, so it’s good to have alternatives. Also, there are cultural issues involved. Some areas most likely would not use earthbags due to their local building traditions. The area I had in mind only builds with concrete, steel, low fired brick and cement plaster. Trying to convince the builders to use unfamiliar materials would be a long, fruitless endeavor.

Also, I was contacted by a group who’s planning a dome housing subdivision. They may build dozens of domes, depending on demand. So the plan I came up with here is a thought experiment inspired by this project. (Not sure if they’ll use my ideas or not. I’m just always searching for viable housing solutions.)

The walls could be built separate from the trusses to speed construction. One crew could be building the walls, while another crew made the trusses. Every truss would be made in a jig so they’re all identical. Also note, they could be curved for added visual appeal.

I suggest using a compression ring where trusses meet at the roof vent. A section of pipe with welded brackets would work nicely (= low cost and simple).

https://naturalbuildingblog.siterubix.com/new-compression-ring-design/

Support the compression ring with scaffolding and braces as the trusses are attached one at a time.

Among our nearly 1,700 blog posts and dozens of articles, there are some real gems. Be sure to read our blog posts about passive cooling strategies if you’re building in hot, humid climates:

https://naturalbuildingblog.siterubix.com/passive-cooling-strategies-for-hot-climates/

https://naturalbuildingblog.siterubix.com/additional-passive-cooling-strategies-for-hot-climates/

http://earthbagbuilding.com/articles.htm#climate