Natural builders strive to reduce their use of cement due to high cost and adverse environmental impacts. Sustainability conscious natural builders might use ferrocement, cement plaster or micro concrete roofing tiles which use relatively small amounts of cement, and avoid more concrete intensive materials such as concrete block. Foamed lightweight concrete is another material that could be added to the list of green building materials. Granted, not every natural builder will agree and so there will likely be some healthy differences in opinion. Anyway, a reader sent me a tip about Allied Foam Tech and I thought this might make an interesting blog post. This material is lightweight, has good thermal and acoustic properties, low water uptake, fire resistance, high early and 28 day compressive strengths, freeze/thaw resistance and it’s available in a wide variety of products. It’s even floatable and can be used to make boats.

“Foamed concrete or lightweight concrete derived from Allied’s aqueous foams are suitable for both precast and cast-in-place applications. Some of the highly insulative cementitious foams at densities 48 kg/m3(3 pcf) to 645 kg/m3(40 pcf) or higher can be used as block fills, lightweight roof deck and void-fill materials. Good strength characteristics with reduced weight make lightweight concrete based on Allied’s aqueous foams suitable for structural and semi-structural applications such as lightweight partitions, wall and floor panels, and lightweight blocks. Cementitious foams derived from Allied’s premium systems are suitable for thin layer coating applications where specific performance criteria are required.

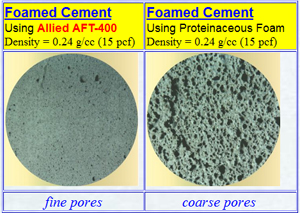

Foamed concrete and foamed cement made with Allied’s foam have very fine pore structure, unlike that made with conventional proteinaceous and surfactant foams. The pore structure of Allied’s foams hardly show any sign of deterioration as the density of the foamed cement decreases to below 160 kg/m3 (10 pcf). At densities below 160 kg/m3, the pore texture of foamed cement derived from conventional foam agents becomes so coarse that most of them show severe structural collapse.

The inert nature of Allied foam systems makes them compatible with different kinds of aggregates, fillers, extenders, retarders, accelerators, colorants, hydraulic inorganics and many other additives.”

Source: Allied Foam Tech.com

Here’s a related product called Biological Concrete, a magnesium phosphate cement that allows lichens, moss and other drought resistant plants to grow on the outer layer.

How seaworthy is foamed concrete? I would like artificial floating islands in international waters.

We can make geodesic dome house from prefabricated foam concrete triangle panels assembled on site by bolts.

You just need one day to assemble the dome !

Send me an email to Lstuantht@gmail.com if you are interested!

Isn’t this fun…. We all are on the same team trying to figure out the secret trade formula for for Al2O3 (alumina) reacting with an alkaline, as SiO2. Those that really know are really really BIG, and do not want any small businessmen to eat into their market.

If you go to my attempt to explain how truly affordable housing will happen, go to http://www.ECO-Foam-Krete.com. And, know we all need to work closely together to make this revolution work.

Here is what I have learned was the Romans built structures of great strength by mixing everything of the same size.

Please forget about mixing in gravel with rock.

And that we will most likely will need a research department to bring together to work how our protucts will work well with a solar and fresh rainwater harvesting roof.

Once again, in a few months will be shipping a totally affordable ECO building cement aftermixture, with Roman cement strong pozzilins that also contains an couple answers to the climate change problem.

I plan to pour foamcrete in place for the walls of our house, and use 3″ iron pipe inside the foamcrete to provide support strength for roof attachment. I’m trying to figure out the window bucks and not having much luck. These are heavy casement windows. What can you suggest?

I haven’t been able to locate any water-tight forms to rent, so we will have to make our own. Do you have plans or suggestions on that?

We have contacted Allied Form Tech Corp for information about their AFT-400 foaming agent. I’ve been experimenting with Drexel FM-160. Have you used that foaming agent before, and if so, how does it compare to the AFT-400?

Thanks!

David

Window bucks are easy. Just use wood. Add metal anchors to attach to the walls. You’ll probably need headers over the windows and doors to carry the load.

I used 1/2″ MDO epoxy glued sign plywood for my forms- bolted together for reuse with poly weatherstripping in the joints. Oil the forms and clean them after pouring religiously .

Use heavier and reinforced (fiberglass fibers ) foam cement with sand in it around the window bucks, which should be held to the concrete with anchor bolts

Hi David

It is not easy to make formwork to hold the foam concrete against your old structures and wall because they are not flat and straight

Further more form works will not costly if you use only one time.

Normally formworks for cast in situ are used for new proj Xt with many repeating works. One set can be used 50-100 time depending on the material.

I may have a solution if you send me drawings or picture of your project.. it is not possible to give you an advise without seeing your actual conditions.

Regarding foaming agent and foam generator, we have all answer for you . We supply them the many countries over the world, including USA

Pls do not hesitate to contact me directly on my email director @thtvietnam.com

[deleted link to spam website… maybe this whole comment is spam?]

Kind Regards

LUONG SI TUAN

Hand phone WhatsApp +84989803595

You may be interested that http://www.FoamKrete.com will soon be able, through ECO-Mining-Milling.com to supply a non-toxic PH neutral blend of a naturally soulible nano Al203 “Alumina powder” and a very solar power pure Si02 “Silica Sand fly ash” aggregriate which will be superior than coal based fly ash, and most likely will bring down the cost of AAC concrete that dosen’t come from a ECO natural blend.

Also on the video http://www.haenerblock.com/making_block.html

After listening to the Youtube video, I found another foam maker schematic at http://pelagic.wavyhill.xsmail.com/cellcrete_how.html

https://youtu.be/sOhQskcslG0

I discovered another video about a foam maker and he uses the Little Dragon.

We can supply foaming agent which give you very resistant foam.It will never break as long as you mix it inside the cement mortar. You can mix the foam concrete all day and the foam does not collapse.

Pls contact me at LSTUANTHT@GMAIL.COM

Thanks

LUONG SI TUAN

I am interested to try your foaming agent, could you please send me more information, Joe Kozy at orion.contracting@yahoo.com I just returned to canada last week but will be returning to Philippines in november, shipping rates to thunder bay Ontario Canada, and also samal, bataan, Philippines. Regards Joe

I suggest you check with http://www.alliedfoamtech.com/Appconc.htm about this.

May I suggest another way to achieve CLC? If you go to http://www.monolithic.org or search for them on You Tube, you will see a video of how they make Monolithic stucco.

What they do is add polystyrene beads to the cement instead of aggregate and only a small amount of sand. The properties of the cement from this additive are unique. The cement won’t crack as it dries, it becomes very lightweight and has an insulation value.

This my solve some of the questions on how to create CLC on a small scale. There are several places on the net listing polystyrene beads in different aggregates specifically for making CLC. What you don’t use, you can then add to your attic or make a bean bag chair.

This information may help. Greentec Construction Technologies (https://greentecct.com/) is located in the US and offers molds and equipment for making cellular lightweight concrete (CLC) products. Products include blocks, panels and equipment pads. Equipment includes portable foam generators and liquid foaming agent.

Dear Friends

I have been in Foam Concrete since 1998.

Our company (www.lightconcete.net) has supplied machinery and equipment for foam concrete to 12 countries around the world, including USA.

I am sure I can help you in answering the questions raised by you in this forum.

Just contact me directly to my email : LSTUANTHT@GMAIL.COM

hi

how to make clc Foaming agent ? what is the formulation ?

thank you

I don’t know the formula. There are two kinds- one based on animal protein, and the other synthetic. You would not want to wash your dishes with either. I am only familiar with the synthetic. The shaving cream consistency bubbles hold up for many minutes before mixing with the cement, and much longer when in the cement/ water mix.

I have pumped the synthetic foam/ cement mix into 6′ x 4″ poly tubes at my shop, put them in a pickup, driven 5 miles, moved the tubes and squeezed out the mix into ground squirrel tunnels an hour after the initial mix. There seemed to be no separation.

I often thought pumping foam into gopher tunnels would be a good way to make them move away.

Business idea ?

Hi friend,

Foaming agents are produced today and supplied by many company at very reasonable price. The portion of foaming agent in foam concrete production cost is less than 5%. So I think it is not worthy to set up a production unit for it if you just produce foam concrete occasionally.

I supply machinery and factories for foam concrete blocks to many countries and we use many tons of foaming agent per year , but we are still buy it from other producer.

I can give you the contact point to buy foaming agent if you want to

Pls contact me at LSTUANTHT@GMAIL.COM

RGRDS

LUONG SI TUAN

Director

THT International Co., Ltd

http://www.lightconcrete.net

i would like to study a lot about light weight foamed concrete.can any body help me

I would like to work on my own small foamed concrete project but having difficulty finding foaming agent for sale and not in huge quantities. Does anyone have information on where I can buy foaming agent in the U.S. Thank you

They just said they use dish soap.

Can you let me know how’s my m3 of foam concrete you want to produce ?

I can make a good offer

Thanks

Luong Si Tuan

I have a 55 gallon drum of foamer and can sell you some. You don’t need much to play with. It is $25 / half gallon, which would make many cu yards of foam. You want a real foamer like this so the bubbles are very small and last a long time.

We call it cast in situ technique

You make the formworks of all your house, including the doors and windows, except the roof, and then pour the Cellular Lightweight concrete (also called CLC for short) inside formworks

You will open the formworks next day to have the house

The roof will be installed later

Such house is very comfortable due to the properties of heat and sound insulation of the concrete. You house is also earthquake and tornado resistant !

What you want for more?

Luong Si Tuan

http://Www.lightconcrete.net

Can anyone direct me to a manufacturer or a set of plans to make a foam machine for CLC in the US? The link above is for a machine that makes CLC cement alone and not just a foam machine.

In addition, it is overseas and when I tried to purchase the machinery it wasn’t a secure selling site. In fact I got several warnings from my Viper program.

I would direct people to http://www.monolithic.org or http://www.monolithic.org/cabins. I purchased the used machinery to create these cabins, and want to make them out of CLC as they would be 1/3 lighter than normal cement.

I have been looking for over a year for a small foam machine or plans to build one as the concrete is batch mixed for spraying on the inside of the domes.

The CLC is lighter and would be stickier so its application would result in less fall out, but the concrete can’t be as runny as some mixes I’ve see on You Tube.

Any help would be appreciated.

B. J. Neyer

I have a foam producing machine (in Mexico until June) and 50 gallons offoaming agent I bought from Goodson Associates in Denver.

We used it to make foam for foam cement which I used in building a concrete house in Mexico.

As I am finished with the job and did not go into the business , I still have the machine and foamer for sale. It would easily produce enough quality dense foam for any use you might have, as these machines were built to inject foam into cement into slurry pumped into large mining tunnels.

The foam cement can be as stiff as you want. The foam cement hangs well on a wall when you throw it, but troweling it causes sagging.

I can send more info if you are interested.

Jerry Jaksha

I’m very interested. Where is the equipment located and what price are you asking?

Bernie

The foam machine was manufactured by Goodson & Associates, Denver CO.

It is variable speed and can produce up to 13 gallons /minute of 2 pound stabilized foam.

The foam is created continuously by injecting their A100 concentrate into a compressed air/water mix. No premixing of the foamer concentrate with water is necessary, Just hook up a water hose, compressed air, 12v electricity, and a bottle of foamer solution.

It was designed to make and inject foam into a transit mixer truck, or into a stream of pumped cement slurry. The machine came with an operators manual and extensive instructions on designing foam cement mixes.

The foamer mix I got with the machine is called Foamcell A-100 and creates foam that lasts 4-6 hours in the cement mix.

The machine and 55 gallons of foamer concentrate cost me over $8000. I would sell it for $3500 as I have retired now and my would be partner is on to other things.

It is in Mexico 6 hours south of Tucson and I could bring it back in June.

Hi, Jerry,

I bought a Goodson A-100 foamer from a guy in CO and didn’t get any instructions. Could I PayPal you $50 to make me a copy of yours? Thanks a lot.

Johnny Gregory

johnnyg8@bellsouth.net

BERNIE,

Did you ever perfect it and find a pump? I’d like to discuss it and possibly hire you.

Randy

I’m sorry Randy I couldn’t get back sooner, I’ve been in the hospital and just got out.

I’ve never pursued lightweight concrete, sometimes called foamcrete for a few of reasons. There doesn’t seem to be foamers available for small jobs that don’t cost a fortune for what they do, except for the Foam Dragon and I’m unimpressed with it. There also doesn’t seem to be an availability to purchase foaming agent in smaller quantities. There doesn’t seem to be any studies on the structural strength of the concrete itself and its varying mixes. Some my disagree with these points, but I’m loath to pass my CC number to some entity overseas.

There is a gentleman in Arkansas who has several videos on You Tube, “Getting Out of Babylon.” He purchased a Greed Dragon and was satisfied with it. He intends to make an interlocking block that you can grout together once you’ve assembled you structure walls. If you search You Tube for the phrase in quotes you should be able to find him.

My interest isn’t in the insulative capabilities, but the light weight. I want to build a Monolithic cabin, http://www.monolithic.org/cabin which are portable. I’d like to decrease the weight by 20% over normal concrete. It would make the structures much easier to move. We simply don’t have the cranes here to move a 24 ft. cabin.

Good point about the lack of testing and various other uncertainties. This field is growing rapidly, at least in Europe, and so we can expect more competitors and more options in the future.

You’re correct on that. I am concerned that if you don’t get the mix correct, the structural integrity can range from acceptable to nil.

A person can approximate the correct measurements of sand, aggregate and cement getting an acceptable result, but not with foam. So much of light weight cement’s strength depends on the structure of the foam and you can’t necessarily tell that by looking at it.

Definitely true. I know quite a bit about concrete with a degree in civil engineering. If the mix is off then the structural integrity can vary widely and even be dangerous.

I can supply the equipment you need

Pls contact me at director@thtvietnam.com

you can see our machinery at http://www.lightconcrete.net

Thanks

LUONG SI TUAN

Hello,

Is the equipment still available, I am in Puerto vallarta Mexico, and interested.

Thanks,

Joe

Contact the company.

Hi Jerry

I am contacting in regard to some postings you made on the Natural Building Blog back in Jan/16, regarding foamed cement. You mentioned you had some equipment and some supplies that you would be interested to selling If it is still available I would be very much interested. If not I would be very much interested in learning where you got your supplies and any other info you could pass on regarding the equipment and the process. you mentioned Tucson, if that’s where live, I’d just mention I am also in AZ. Hope to hear from you.

Hi John Taylor

I have everything one may need for foam concrete application

Pls visit http://www.lightconcrete.net and contact me at latuantht@gmail.com if you need anything

Rgrds

Lstuan

HI John

I have the foamer here in New Mexico. The foam/metering machine is in Mexico and could not be brought back until December.

I can send a quart of the foamer and instructions to you for $15 +shipping. You can do experimental batches using an electric drill with a brush to make the foam.

A quart will make many yards of foam to experiment with.

Check out the Litebuilt.com website to get an idea of foam concrete possibilities.

Jerry Jaksha

Hi Jerry

Thanks for your response. Yes I would like to buy a quart from you. You cam PM me at jrtaylorinflag@gmail.com to arrange payment. Regarding Litebuilt, I have visited their webpage as well as many others. They do appear to be a large player in the CLC industry. In fact Foamed cement for construct appears to be used all over Europe and every other country in the world except the USA. Having been involved in construction in the past,I have my suspicions why.

BTW I have spent a good deal of time living and working NM. Would you happen to be in the Santa Fe or Silver City areas? Latter. John

Jerry, would you be willing to also send me a quart? jason@traderhill.com also interested in your machine if you havent found a buyer yet…

Hi, Jerry. We talked about your copying the INSTRUCTIONS for the Goodson foam generator I also have (w/o them). Would you please get in touch again?

Thanks, Jerry.

Your friend,

Johnny Gregory

Healthful Living Organic Farm

Madison,NC(336) 541-0421

johnnyg8@bellsouth.net

Hi Johnny

How is life on the Farm? Hope is all going well. I do have the instructions. Did you not receive them with your machines?

Dear Neyer

CLC can not be applied by spraying method. It is poured into the place where you want it to be as it flow like water

So you can make a dome formwork and pump CLC in it from top. This is possible as long as you can make the form work to hold it it; that mean the form work must be firmly closed

We can supply equipment to produce CLC, but dome form work must be engineered locally

Regards

Luong si Tuan

http://Www.lightconcrete.net

Hi Mr Neyer

We are very sure that we can meet your demand

Pls visit our website : http://www.lightconcrete.net

then send me a message to LSTUANTHT@GMAIL.COM

I have helped 2 person in this forum to buy foaming agent from UK and I have supplied a foam generator for one of them yesterday.

We can supply complete plant for CLC production of capacity from 10m3/day to 250m3/day.

I hope we can cooperate.

Kind Regards

LUONG SI TUAN

what other foaming agents have been used with success

https://naturalbuildingblog.siterubix.com/air-crete-building/ Check out this blog post about foamed concrete domes. They use regular dish soap. Can’t get much easier than that. They even sell a low cost kit that mixes the foamed concrete. Be sure to watch the video where they explain their latest foamed concrete dome ideas. It’s excellent. (Before they struggled with concrete block.)

The website you are referring to, made CLC blocks and then mortared them into a dome using a process of support similar to how the Romans built their structures.

The machine makes CLC slurry with the lowest structural integrity without any aggregate. Typical concrete weighs 140-150 lbs. per cubic foot. That CLC weighs 50 lbs. per cubic foot. I need to make concrete with aggregate weighing around 105-120 lbs. per cubic foot.

I tried to purchase it, and as indicated in a previous post their website was over seas and not secure. I was unwilling to risk my credit card number.

Bernie

Dear friend

My company can supply all types of equipment for foam concrete production

We have been exporting to many countries around the world and we are probably the most versatile company in foam concrete equipment supply at this moment

Pls contact us at http://www.lightconcrete.net

Thanks

Luong Si Tuan

Director

I invite people to view the web site, http://www.monolithic.org/cabins.

I am seeking to build these out of CLC. They are portable, but the largest weighs 14 US tons. If I can make them 20% lighter, it saves 3 US tons and a smaller crane can move them if needed. My plans though are to build them in place. My state, Kansas, doesn’t tax a business’ personal property, and these would qualify as personal property, so it would significantly reduce my costs and I could provide affordable housing to lower income individuals.

At the web site, there is a You Tube video of Monolithic building these units. I have the mixer and shotcrete machine to build them. You batch mix the concrete in 1/4 to 1/3 a cubic yard and dump that in the shotcrete hopper for shooting on the inside of the building. For this reason, I don’t want a large volume foam machine. We will scoop the aggregate, break two cement bags into the mixer and mix the ingredients dry, before adding treated water. If instead I add foam to the desired consistency, we will get a tackier material with added insulation capabilities and a lighter product.

Bernie

I saw the video and think that the wall of that dome was made from ordinary concrete applied by shotcrete, not foam concrete. The same method is used for building of 3D wall, swimming pool, tunnel, etc

But I think the dome can be made of foam concrete as well, as long as the foundation is made from normal reinforced concrete to support the structure

The foam concrete will be prepared at high density and mixed with fiber

More details can by discussed further on with interested person

Blessing

Luong Si Tuan

I’m sorry, but you are mistaken. There are different grades of CLC. You are referring to the weakest mix that consists of cement, fly ash and foam, mixed in a slurry.

There are different grades and mixes. I am referring to a concrete consisting of cement, aggregate and treated water. This mix may contain fly ash as well. If, instead of just treated water, I add foam, I get a concrete approaching the strength of normal concrete at 1/4 less weight.

Your slurry mix isn’t intended to replace normal load bearing concrete. The concrete Monolithic uses had perlite added for air entrainment. The longer you mix the concrete the better it works because you entrain air through the mixing process.

I am sure that I can create a CLC that can be pumped and shot with a weight reduction of about 20%.

My training at Monolithic was for the most part to learn about how to make a,stackable, strong concrete that would produce a tornado proof structure.

My sole problem is finding an affordable foam machine so I can batch mix the concrete.

Bernie

I have a foam machine which makes the foam which can be injected into a pumped water/sand/cement mix -made by Goodson Associates from colorado. Am interested in selling it and 50 gallons of foamer concentrate.

Jerry Jaksha

Yes, I replied previously. I am interested. Please tell me about it, model, price and when you bring it back to the US, where it will be located.

Bernie

Dear Bennie

Can you give me your email so that I can send catalogue, video and quotation? can you tell me what capacity you want? (how many cbf or litter of foam in one second or minute?)

Thanks

LUONG SI TUAN

email: director@thtvietnam.com

Dear Bernie,

I think you are right! We can spray the CLC which will have has high density after breakage of foam…

I have been working in shotcrete ( we are dealer of Aliva) since many years, but we never try to use CLC as shotcrete material before! We also have been in CLC industry since 1998 but never used it in shotcrete! This is the first time we hear about this! Strange? Anyway theoretically I think it is possible and I will try it some time!

I hope you will share your experiences with me, if possible.

Regarding your need of foaming machine for foam concrete, I can supply you a small unit which is compact and light (7kgs 04 15 pounds in weight) and can spray about 200 litters of foam per minutes. I also have other unit which has higher capacity ( 650l/min) if you want. Both are run only by compressed air and very safe to you in mobile jobs.

Pls send me your email so that I can send you more details.

You can download information about them from our website http://www.lightconcrete.net

Thanks

LUONG SI TUAN

Foam concrete strength and insulation can be varied by adding more or less foam to the mix. The cement amounts per cu yd are the same as normal concrete, so material costs are similar per yard minus sand and rock. A cu yd would still cost $60 – $70 for cement.

A continuous mixer / pumper ( add cement, water, and foamer, would make it much easier to use. It is so light, it sticks in the mixer, and transport buckets.

You can also mix the foam with sand only and make quicksand pits just like the movies.

It is easy to mix small batches. Just whip up the 40-1 mix into a froth with a drill powered wire brush , mix a cement/water paste , and mix the two with a paddle.

Some excellent uses are:

foam cement on the roof of concrete roof buildings

foam cement fill under the concrete floor of any building

non structural walls instead of concrete blocks

fire resistant door fill (better fire resistance, insulation, and lighter weight than standard gypsum fire doors.

It can be pumped to fill gopher tunnels hundreds of feet long.

non compressing trench fill under pavement repairs

Foam concrete feels cooler when hot and warmer when cold because it is less dense, like wood compared to steel.

It does require better curing techniques than normal concrete because it takes longer to gain strength.

I am experimenting with additives for more tensile strength and faster curing. You can’t add latex to the finished mix (kills the foam), but blending the foam into a latex additive/cement mix works.

It doesn’t replace normal concrete, but I wish I had used it under my hot water heated concrete floor, and am happy I used it on the roof of my concrete Mexican house.

If you want some foamer to make your own, it is very cheap. A gallon( $50) will make 12 cubic yards of foam to mix with your cement and water.

Hello,

My name is Thomas Langlade, I am an intern at CU Boulder (Colorado) and I study the foamed cement, a blend of cement, water, additivies like silica-fume or fly-ashes, and foam (made from foaming agents and water). There are no aggregates in this product. If you have such products, I will be interested in ordering some.

Thanks by advance,

Thomas

Any experience with the ‘green dragon” or “little dragon” DIY foam generator? I am concrete artists and want to make small bathes. I am located in Kansas City, Mo. See this site for the machines http://www.domegaia.com/tools.html

Mike, Ive not heard of this one, but looks like a cool unit for a smaller batch…im in kc as well, and will post more as i experiment this summer, I know that there is a type of foam used in the well drilling industry that resists bubble collapse too.

I found plans for a foamer on YouTube. It had a schematic and build layout. You would still need foaming agent, but was equal to the Green Dragon.

I can only speak for myself, but I don’t trust giving someone in another country my CC number.

Can you post the youtube link?

When I previously replied I was doing it from my phone, so I couldn’t jump around and get what I needed easily. If you but search for foam generators, you’ll find a lot there.

I found it again and here is the link. https://youtu.be/MjhUJ5zNg60

If you are making small batches, a rotary wire brush ( with an extension drive shaft) in a 110 v drill will whip up 5 gallons of stiff foam very quickly.

You will find that it is more difficult to mix cement with water than to make foam and mix it into the paste.

Please let me know if you ever find a continuous mix moarter machine.

I had no luck with soap bubbles- mine don’t hold up . Don’t give up without trying commercial foaming agent.

One thing most people ignore is curing (keeping it wet) the foam cement for at least a week. Cement needs time and water to become strong.

If you know your chemistry, here’s a recipe for a foaming geopolymer:

Water:17.33 moles

K2O 1.630 moles

SiO2 4.46 moles

Al2O3 1.081 moles

(The silicon dioxide and aluminum oxide can be found in a lot of minerals, just need to be sure the ratio’s about right)

220 g muscovite mica (can probably substitute w similar minerals)

90 g powdered filler (recipe calls for calcium fluoride, but again, experiment, can probably substitute with anything of similar particle size)

Let stand for 1 hour at room temperature.

Add 50g hydrogen peroxide (110 vol), 120g portland cement or ground granulated blast furnace slag, and 100g of water.

The slurry should start to expand almost immediately and is hard after 3 hours at room temperature.

Be careful, the binder will be quite caustic. Should make 860 g of foamed geoploymer, around 2.8 times more insulating than foamed concrete, and is supposed to allow water vapor transport for passive cooling. Haven’t actually tried it yet, but it’s in Davidovits’ geopolymer textbook.

The foaming agent costs about $50/gallon in 55 gal drums.

It is mixed at 40-1 with water, then foamed in a air injection machine, or small scale with a wire brush and drill

Cement used is the same amount as regular concrete, just the large stones are replaced with the cellular foam, so it is not cheap.

Pumping it is almost necessary because it is so light and sticky it stays in buckets and wheelbarrows.

Very interesting material, but requires different mixing and transport methods.

I am building a diy squeeze pump and use a water reducer to easier mix the cement and water. My hope is to use the large cmc machine i have to “print” foam cement pieces.

It sounds good!Where did you find that price? Which is the brand of the foaming agent? thank you so much for the infos

That cost hasn’t been confirmed as far as I know. Always check current prices.

The $50/ gallon was what I paid in a 50 gal drum. I am selling from that drum

I bought it from Goodson and Associates in the Denver area with a foam generator. They use it to fill old mine shafts.

The foam concrete is used for non structural walls and horizontal sub floors much more in other countries than the US. A contractor in ABQ. NM adds foam concrete to insulate and add pitch to flat roofs.

Thanks for the update.

Interesting subject this foamed concrete. Seems like we DIY’ers can’t just go down to home depot & buy a can of foaming agent aside from buying a bottle of dish soap from Safeway. Looks like a foam generator is needed in addition to the foaming agent to make this stuff. However,found one post on U Tube where the guy mixed a 2 part liquid in a bottle, transferred it to a bucket & mixed with drill paddle to make foam & put it in mixer by hand. Maybe I’ll try squirting a can of shaving cream into to mixer & see what happens.

Dear John

Foaming agent give you foam which does not break when you mix it inside concrete mortar and keep the volume of Clc constant during the curing

Shaving foam will collapse when you mix in concrete.

You need to buy a small foam generator and compressor to blow foam

Am I correct to assume you could use this material to spray inside and out of an earth bag building? If so, what are the prices compared to using just concrete?

Yes, there are many uses.

It’s a specialty product so the price is probably higher than regular cement.

The higher price is a turn off right away. I find it interesting that products, food that are better for the earth or use less drugs seem to always cost more. Poultry and beef that do not use chemicals cost more. THAT has always confused me. It’s cheaper but healthier, pay more. It seems the same with this product.

This specialty cement requires extra materials and processing, and so a higher price is reasonable. It’s less expensive to mass produce ordinary cement that’s used 99% of the time.

So, it actually will be cheaper in the long run to use this product? And, will stand up to regular mortar longer? What’s the mix ratio per bag of cement and sand?

You have go analyze it on a case by case basis. You may not even need it. Typical concrete works for 99% of applications. Search their website for details, think it over and then call their tech department if necessary.

Thanks. I guess a little more research hunh?!

Owen, do you happen to know the R-value of this product? Or the cost?

You’ll have to ask them.

One very interesting application is making sections of domes one at a time and assembling later. I saw an article that described the process about 20-30 years ago and can’t remember where I read it. If anyone knows the source, please let me know. The author used a simple form to make sections of a dome.

Another reader is planning to form entire domes and pump in the foamed concrete all at once to build instant houses.