We continue to get quite a few inquires about compressed earth blocks / soil-cement blocks. This Mother Earth News article got me excited about pressed earth blocks years ago. It’s an oldie but goodie first-person account of a couple in Arizona who used the soil on their land to make CEB blocks that cost 97 times less than cement blocks.The authors do a great job of summarizing the entire block making process in non-technical language. They recommend soil with 75% sand, 15 to 20% clay, and 5 to 10% silt. The only tools used were a pick, shovel, hoe, sprinkling can, sifting frame and a CINVA Ram (CEB press).

Make Your Own Bricks from Soil is another old but good Mother Earth News article that describes how to build CEBs in rainy climates.

From Wiki: “The advantages of CEBs are in the wait time for material, the elimination of shipping cost, the low moisture content, and the uniformity of the block thereby minimizing, if not eliminating the use of mortar and decreasing both the labor and materials costs.

– CEB can be pressed from humid earth. Because it is not wet, the drying time is much shorter. Some soil conditions permit the blocks to go straight from the press onto the wall. A single mechanical press can produce from 800 to over 5,000 blocks per day, enough to build a 1,200 square feet (110 m2) house in one day. The Liberator, a high performance, open source CEB press, can produce from 8,000 to over 17,000 blocks per day.

– Shipping cost: Suitable soils are often available at or near the construction site. Adobe and CEB are of similar weight, but distance from a source supply gives CEB an advantage. Also, CEB can be made available in places where adobe manufacturing operations are non-existent.

– Uniformity: CEB can be manufactured to a predictable size and has true flat sides and 90-degree angle edges. This makes design and costing easier. This also provides the contractor the option of making the exteriors look like conventional stucco houses.

– Non-toxic: materials are completely natural and do not out-gas toxic chemicals

– Sound resistant: an important feature in high-density neighborhoods, residential areas adjacent to industrial zones

– Fire resistant: earthen walls do not burn

– Insect resistant: the walls are solid and very dense, discouraging insects

– Less skilled labor is required; wall construction can be done with unskilled labor encouraging self-sufficiency and community involvement.”

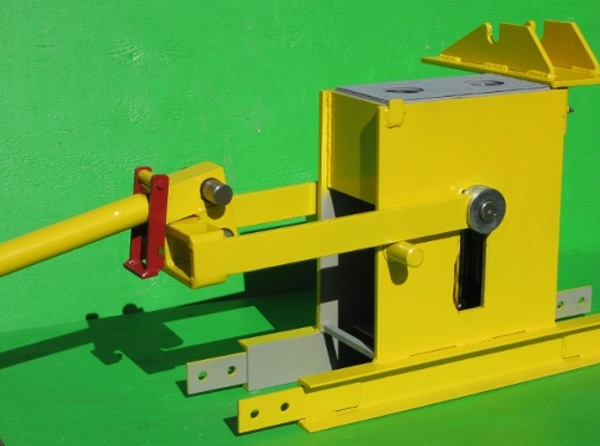

The Fernco CEB press is the only brand of hand-operated presses available in America to my knowledge. Their MP-612 press now costs $1,538. Compare to Star Top presses that currently cost $836, but must be imported from Thailand.

You could make your own press with open source CEB press plans.

The best soil for CEBs is a pulverized and screened sandy-clay soil with just enough non-expansive clay to make strong blocks. Be sure to remove all organic material such as leaves and twigs. Test your soil according to the directions in the above articles, or buy from local suppliers who specialize in CEBs.

More good info about building with CEBs:

Grassroots Communities

Star Top CEB Presses

Dwell Earth

Auroville Earth Institute in India (highly rated machines)

CEB Floors by Vela Creations

Image source 1,3: Star Top Interlocking Brick Company

Image source: Fernco

Image source: World Nomads.com

Very interesting

Thank you sir

please inform me to how can buy your machine in india

I want to get price on delewary to india

HI.

How are you?Iam Hamed Almazloom from Iraq I live in sydney Australia .I need to buy this machine for automatic press bricks machine or compressed earth blocks(CEBS) tell me about the a good price for all equipment of the this plant

With my greeting and best wishes to all

thank you so mach

Contact the company.

Dear Sir,

i try to buy it from some companies in Thailand but they said i have to come to learn.i and my friends no time to go thir. we need only construction design we can pay for it.

we are planning for 3rd.World a small NGO project to help them.

Thanks

Like I said, you can’t buy their plans. They don’t won’t people to copy it. The only plans for sale on the Internet are lower quality designs, although they would still work for many years. Keep looking for other brands. CEB machines are sold all over the world. I would only make one as a last resort.

Well, a Thai guy told me the wider the walls the better isolation you get from heat, especially here in southeast asian countries. Certainly if I build with double width walls its going to be more expensive. I just wonder if this CEBs are good enough to keep the rooms cooler than by using single brick walls. I don’t have experience with CEBs yet as you can see.

By the way, I am making my own press machine. It is going to be similar to the Fernco CEB press shown in an image above, but it is my own design. To make one like that one is much cheaper than buy it ready made, you just need to fine a good metal-mechanic workshop that follow the instructions properly. If I get my own CEBs as I expected I will let you all know here.

What that guy told you is true. But it comes down to a matter of how much are you willing to spend. Remember you’d be doubling the materials, doubling the foundation, doubling the labor… I would rather spend my money on wide roof overhangs or wrap-around porches so less (or no) sun hits the walls. Use lots of windows for good cross ventilation. Use high sloped ceilings with roof vents. Use plantings around the house, etc. etc. We list dozens of low cost/low tech methods like these to keep houses cool in hot climates. Search our blog for “passive cooling strategies” on a major search engine. (Our search engine is bogging down and producing lukewarm results.)

Hi Geiger

It is true there are some cebs plans online, however, they’re not as good as these machines.

how can i get a good one as PDF

Thanks

I agree. You can’t get plans for the best machines. You have to buy the machines already made. They’re reasonably priced, and the best ones can last 100 years in my opinion. The main challenge is one of access — deciding which one to buy, translation/language difficulty between countries, shipping, etc.

Hello there

I have a small land and my project is to build a small two stories house in it. Using compressed earth bricks like these sounds nice and green to me and at the same time more economical. However, what advise could you give me to build this house? Should I put reinforced concrete columns in order to support the load of the slab and the second floor, or should I refill the brick’s holes with concrete and mild steel rod to do the trick?

Also, should I use single brick width walls or double brick width walls?

Thanks

You can use both methods — infill with CEBs between a post and beam frame or add rebar and cement grout in the holes. It mostly depends on what look you’re after. Concrete post and beam (confined masonry) is stronger but more expensive. No need for double wythe walls in most cases. This is mostly done in cold climates.

Hi, I am very interested this machine,if someone help me or can tell me where and how much can I buy only contstration design this Manual ceb machine fo our small NG0s project I would greatly appreciate it and Good blessings you.

Mekonnen

There are plans you can get online, however, they’re not as good as these machines in my opinion.

Sir how do you make pavers and tiles with this mixture of soil and cement.we make blocks but not pavers and tiles

https://naturalbuildingblog.siterubix.com/ten-earth-floor-methods/

How can I get information about startop. I have written the company but no response. I need the machine badly for my home construction. Your lead will help. Thanks

The problem is their lack of English skill. You need to find an English speaker in Thailand who also knows Thai.

If you can’t find someone, send me an email. My address is at the top of the page.

Dear Sir

How are you doing

We are looking for brick production line of soil

We provide our clay or soil, of course, prefer the soil?

What do you advise that confuse with the soil in order to be a very strong product bricks bear the weather conditions if it is rainy or cold or hot or moisture, etc..?

Also bear the weight of the roof? We are building system we have Concrete roof directly above the bricks?

We also want colorful decorative bricks outside of the buildings.

Does the product need bricks to spray water – how much time needed until used in construction

Size bricks

Standard Break 240 × 115 × 53

Hollow brick 240 × 115 × 90

Hollow Brick 240 × 190 × 90

Hollow Breaks 400 × 200 × 150

With best wishes to you

Burhan Alani

Mob- 00971502667452

There are many types of soil — hundreds or maybe thousands. You have to learn what works best in your area through experimenting, talking to brick companies, engineers, universities, etc. Take notes! Good luck.