One way to speed construction of compressed earth block walls (CEBs) is to pour concrete posts after the CEB walls are built. This process may be desirable in mild climates where there’s low probability of rain or snow and you are eager to get the walls built. Pouring the posts in the walls saves on form material, and reduces cutting and fitting of blocks (less need for perfect alignment). Posts are inconspicuous (or invisible in some cases – see below) because they’re inset flush to the wall.

Summary of the building process:

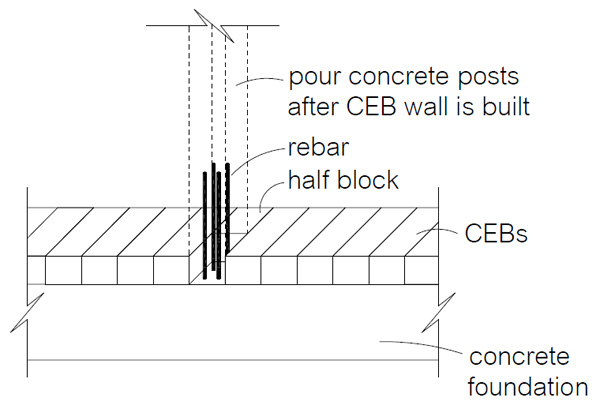

– Rebar protrudes approximately 2 feet above foundation at the location of every post.

– Stack the CEB walls, placing a half block (CEB cut in half) next to where the post will go. This will create a beautiful, uninterrupted earth block wall on the exterior. In other words, the posts are not visible on the outside of the house.

– Attach additional rebar after the CEB walls are complete. Tie the rebar to that which is sticking out of the foundation. This rebar is then connected to rebar in the concrete bond beam to make a very strong framework. Designed by an engineer, this method could meet code even in earthquake zones.

– Optional: mask off CEB wall on both sides for a neater pour and to reduce cleanup.

– Place an oiled form board for each post against the wall and brace in position. The form board needs to be slightly wider than the width of the post (wall cavity).

– Pour the concrete, being careful to eliminate voids.

– Remove the form boards after the concrete is set up.

– Posts can be hidden by aligning them with interior partition walls, placing in closets or behind cabinets. If nothing else, they could be painted a neutral color so as not to draw attention.

Alternatively, you might want to build the posts first. Building the post and beam frame in advance (before stacking CEBs) enables you to complete the roof so you can work undercover in the shade, out of the elements. This reduces risk of moisture damage to the blocks and makes for a more pleasant work environment. There are pros and cons to each system. Use what makes most sense in your particular case.

Note: Concrete posts are not always needed, of course. Talk to an engineer about your project.

Hmm is anyone else experiencing problems with the pictures on this blog loading? I’m trying to figure out if its a problem on my end or if it’s the blog. Any feedback would be greatly appreciated. chloe

It is working correctly.

I really like this “hidden post” via half block concept. Tieing the foundation rebar to the post rebar to the bond beam rebar sounds so secure!

Yes, it’s very strong. The short riser rebar is tied together before pouring the foundation, so the connections are embedded in concrete. And, of course, the rebar cage for the posts are embedded in the concrete posts. This system can withstand earthquakes if it’s designed and built correctly. One tip is to add mesh on both sides of the CEB blocks, tied together through the wall, then plaster both sides.

The only constructive criticism i have is that most of the posts don’t have adequate instruction or video. Would be very hard to follow instructions.

Thanks for the feedback. It would take too much time to write full length, detailed articles for each topic. My intent, my approach is to bring up various possibilities and point people to resources with more in-depth information. People can also google the keywords in the blog posts.

That’s the way we did our walls, and it works really well. We did the same for window framing, lintels, door framing, etc. Just pour the concrete after the bricks are in place, and everything is locked in.

http://velacreations.com/shelter/building-materials/dirt/item/49-ceb.html

http://velacreations.com/shelter/building-components/walls/item/165-brick.html

Great, thanks for sharing. I’ll read this soon. It looks like you did your posts a little differently. You probably noticed how my drawing shows blocks turned perpendicularly to create 10″ walls with the posts inset in the wall. Goes to show how there are lots of ways of doing things. I like to look for new and different techniques.

Edit: This looks great, Abe. I plan to publish a blog post about your project tomorrow. There are so many ways of doing things. It really, really helps to see various building systems and then weigh all the pros and cons. And like John said, it helps to have more thorough explanations with lots of photos and/or video. However, there isn’t time to write long, detailed blog posts every day, so I’m glad we can point readers to your site and others of that caliber that have the necessary details.

I also wanted to say how I really like the look of the finished walls. It’s not crude looking and they’re not fussy-to-build perfect blocks. The edges are slightly irregular, giving it the sort of handcrafted look that’s most appealing to me.

I like 10″ walls for stability, but they use a lot of blocks. Your method uses 1/2 the materials and way less labor. Plus, you’ve achieved a nice brick wall using dirt cheap earth blocks.

Thanks for your comments, Owen. We like the walls, too, they add a bit of color and dimension to a room that you can’t get with sheetrock.

In our climate, the 6″ walls work just fine. If I were building for a colder place, I would probably do 2 6″ walls, separated by a 4-6″ insulation cavity.

we have experimented with a lot of different building materials (like you can see on our site), and CEBs are one of our favorites, especially for floors, where mortar isn’t required.

One of these days, we want to build a CEB vault, as it’s one of those things we have always wanted to do.

Yeah, the color is particularly nice. I like subtle changes in color like that. Very natural and soothing. Completely uniform blocks would get boring. And no plaster needed. The absolute worst would be gray concrete.

One drawback though is mortaring the block. I hear that dry stack is 2-4x faster. But again, that means thick walls and large blocks.

What kind of CEB press do you have? They last a lifetime. A community could pitch in and buy one and you could build a small town over the decades.

Our blocks are locally produced. They measure 12″ by 6″ by 3″ tall. They are stabilized with 5-10% cement, I believe. We purchased 3000+ several years ago to do our floors and various things around here. We still have 1000+ or so. We’ve used them for all sorts of projects,from garden borders to rocket stove mass. They are extremely versatile.

the machine they use to produce them produces 8 blocks at a time, probably around 16-24 a minute. That things runs continuously, all day long.

They sell the blocks for about $.25 each, including delivery.

Dry stacking could work, but I worry a bit about the surface bond sticking to the blocks, because it doesn’t have the texture like concrete blocks. If one were to do it that way, the best thing would be to include some nylon mesh to help reinforce the surface bond. I think it would be possible, but we found that mortaring really didn’t take that long, and we were inexperienced when we made those walls.

Thanks for the input. Buying blocks might be most practical for some.

buying blocks has a lot of advantages, especially if they are produced locally. Not only are you supporting local businesses, but you are not investing in the infrastructure required to make the blocks. For just one house, the prices of these machines is not worth it. But, if someone in your area makes a business around it, the machine costs is divided amongst numerous projects.

I agree. I wish someone was selling these blocks locally.