Breaking news. This just in from Brandon Ross, P.E. whose team has just completed an earthbag wind test in Florida. Text is from his preliminary report. Final results are expected to be published in a few months.

“The University of Florida chapter of Engineers Without Borders has completed wind testing of an earthbag wall. The project was conducted in support of Barrels of Hope, a Gainesville, FL based NGO that provides development assistance in Haiti. Test results will guide Barrels of Hope as they work with Haitians building earthbag shelters.

Testing was conducted at the Powel Family Structures Laboratory at the

University of Florida, using the high airflow pressure loading actuator, or HAPLA system. The HAPLA system generates out-of-plane (broad side) pressure on wall specimens, which are placed in front of the HAPLA pressure box. The HAPLA system is capable of generating quasi-static and dynamic pressures.

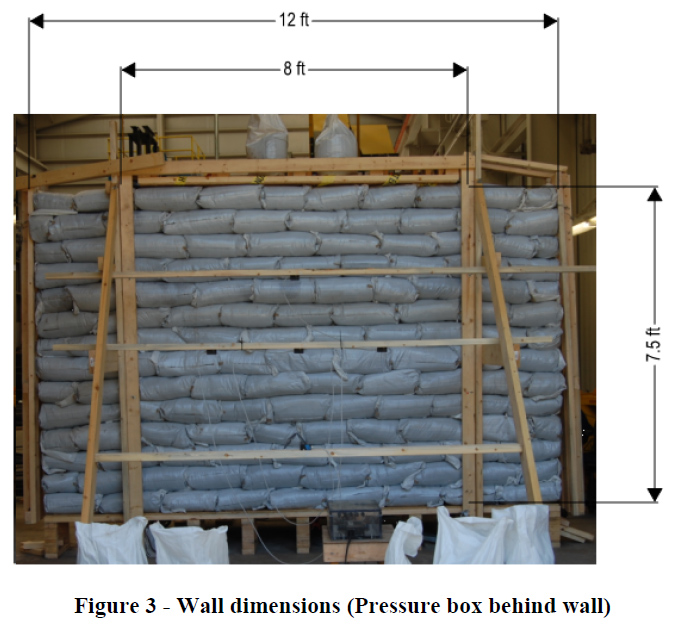

The earthbag test wall was approximately 14 in. thick x 7.5 ft tall x 12 ft long. Bags were filled with a slightly moist sandy-silt. Each course was approximately 6.5 in. tall, and was compacted by a tamper. Two rows of barbed wire were placed between each course. The wall loading and restraints were designed to mimic conditions present in earthbag shelters. The center 8 ft of the wall was pressure loaded by the HAPLA. Two earthbags were placed on the top plate to simulate the dead load of the roof.

The completed wall was subjected to out-of-plane dynamic pressures up to 30 psf and quasi-static pressure up to 60 psf. Out-of-plane displacement was monitored at (5) points on the wall using string potentiometers. Analysis of the load and displacement data is underway, and preliminary results are encouraging. The wall did not collapse during any phase of testing, and was able to support approximately 30 psf prior to undergoing permanent displacement.”

I see that this test is from 2011. What was the final result to the testing?

All known earthbag tests are posted on our Testing page at Earthbag Building.com.

http://earthbagbuilding.com/testing.htm

Next Monday, May 9th, we take the recycled plastic block house we built for the Hunt Institute for http://www.eandhweek. org to Norman Oklahoma for some testing.

As I understand at this point in time, one of the tests will involve pressure applied to a corner to test shear strengths. Another test will test the strength of a wall. It is considered a destructive test. The cute little house will be destroyed in the process.

Again, this is as I understand it at this time. I haven’t been pressuring them for information because they are doing the testing for free.

I know the building will do fine in a seventy mile an hour head wind because we’ve done that moving the building from the SMU campus. It is secured to the trailer by D rings welded to the base. All we did to prepare the building for moving was wrap it in plastic because it is covered with clay and the last thing I want is to be pulled over for unsecured load if some of the clay fell off going down the highway.

The house will be hauled to the Fear lab at OU with the same tie down method. All I’m going to add to the house for the trip is two pipe skids running end to end to make it easier for them to move around at OU.

One of the problems some out there might be able to help me with is OU has a shake table. But it only moves in one direction and is four feet by six feet. The house we built at SMU is eight and a half feet by twelve and a half feet. I would like to build a model or sample that could give us an idea of how strong the wire instead of mortar concept would be in an earthquake.

If I cut back the size of the structure to where it would work on their table then I would need to use four by four by eight blocks. That would require a special press just to make the blocks. I can do that if that is what it will take to do it. But I would much rather find another way that won’t involve so much time, materials, and effort.

Owen, Thanks for your post and your questions.

We did not use clay in our soil. This decision was made because of the limited window we had with the HAPLA system. We had to build, test, and deconstruct the wall within a week. There was little or no time for drying of the soil in the wall. Working with Barrels of Hope, we decided to use an available source of top soil as this would be a worst case scenario. The house Barrels of Hope built in Jacmel, Haiti DID have a blended clay-sand mix. As we have discussed previously, use of clay & sand is certainly the best practice.

The bags in the test wall were compacted at every course. After compaction the earthbags were stiff (you wouldn’t want to kick them, lest you hurt your toe), but because the soil lacked clay there was no cohesion. The effect of not having cohesive-dried earthbags will show up in increased out-of-plane displacement due to compression on the windward side as the wall spanned vertically foundation-to-roof. This effect appears to have been less critical than sliding between the bags as the wall spanned horizontally wall-to-wall. These topics will be discussed in much more detail in the forthcoming paper.

I caution against generalizing the results to all earthbag dwellings. Our wall test had certain boundary conditions and materials that may or may not be present in other earthbag structures. “Your mileage may vary.” That said, the initial results confirm the potential of earthbag structures.

Thanks Brandon. The test is still very useful. It shows even minimal strength earthbags can withstand a great deal of force. Thanks for all your help on this project.

FYI

at 25°C (77°F) with air density 1.2923 kg m-3

Equivalence of 30 psf:

wind speed:

– 47.149 m/s

– 169.74 km/h

– 91.65 knots

– 105.47 miles/h

– Beaufor : 15 (limit of scale)

pressure : 1436.4 Pa

Equivalence of 60 psf:

wind speed:

– 66.679 m/s

– 240.04 km/h

– 129.61 knots

– 149.16 miles/h

– Beaufor : 15 (limit of scale)

pressure : 2872.8 Pa

Source: http://www.cactus2000.de/uk/unit/masswsp.shtml

Thanks for the input.

I’ll try to get Brandon to answer some questions about this test. Here are my questions so far.

1. Did you add any clay to the sandy-silt soil mix? (Did the earthbags turn into hard, solid earthen blocks after drying?)

2. Did the earthbags dry out before the test?