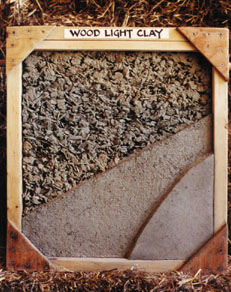

Woodchip/light clay is a traditional building material in Germany and other European countries. It’s typically used as infill between timbers in post and beam construction. I’ve been told that bags of pre-mixed materials are standard items in building supply centers, and blocks can be made to order. The drying time, shrinkage and labor are less than using straw/clay.

Although no one to my knowledge has used woodchips and light clay in earthbags, this building system has good potential and so I’m planning to build a test wall — maybe one wall of a garden shed.

The building process is very simple. Thin clay slurry is mixed with chips and used as fill material in the bags. Clay holds the chips together and protects the wood from insects, mice and fire. Clay also absorbs odors, moderates humidity levels and provides thermal mass to help stabilize indoor temperature.

Advantages: Low cost, possibly free materials; lightweight; reduced labor; faster to build than soil-filled earthbags; easy to mix; very little tamping; non-toxic; locally available natural resources; sustainable and recyclable, approximately R-2 insulation.

Chips can be up to 2” diameter. They should be bark-free, since bark decomposes rapidly. Chips can be dry or green, and often can be obtained for free or very low cost from city recycling programs or tree trimmers. The ratio is 4 parts woodchips to 1 part clay slip.

One drawback is drying time — about 8 weeks for a 12” thick wall during warm weather, and even longer for 16” walls. Builders in cold climates would have to plan accordingly to allow adequate drying time and prevent freezing. And like typical earthbags, walls must be protected from the elements with adequate roof overhangs. Risk of moisture damage probably rules out the use of woodchip/light clay for domes.

Photo credit Frank Andresen

More details are available here.

Hi do you perhaps have the quantities of woodchip & soil per cubic meter of wall?

In comparison to light clay straw, will light clay woodchips use more woodchips or less?

Thanks Madeleine vdB

I sent your query on to the straw/clay specialist and he is off to a workshop and will hopefully answer when he returns…

Hi Madeline-

It’s actually much easier to calculate the volume of wood chips for a slip-and-chip wall than it is to calculate straw for LSC. For wood chips, you just need the same volume of chips as your volume of wall, so 1 cubic meter of chips for 1 cubic meter of wall. Clay soil is a bit more tricky since the amount you will need will depend on the purity of the clay source. I generally use 40% as much clay slip as chips by volume. Clay soil expands a bit when it is turned into slip, but not by as much as you would expect. So I would plan to have soil on hand equal to about a third of the volume of the wall. But you should definitely do some tests and determine your final recipe before being too confident with that number.

good luck!

Michael

I live in Alaska and have massive amounts of wood chips available however I would have to truck my clay a fairly long distance. My question that I’ve never seen addressed is how much clay per-cubic foot of wood chips would be considered standard? Does anyone know?

Dry mix weight of clay to straw for insulating walls in northern climates = 35/lb/ft3

Wood chip/clay should be in this ballpark. Experiment to see what works best, buy a book on this building method and/or try emailing the author.

The R-value of wood chip/clay is around R-25 for a 12″ wide wall. Freezing weather can damage the walls if they’re not dry, so be sure to allow plenty of drying time.

Did you build your test wall? We are thinking of trying this and straw-clay test walls in a shed next year prior to building our house the following year…

I think this method has a lot of potential, but I live in a somewhat remote area and never found a source of wood chips. Branches are discarded here, not chopped into wood chips. Need to find someone with a machine.

You’re building on a tradition going back hundreds of years, so the technology is extremely well proven. It even meets code in Germany where they have some of the strictest codes in the world. Using bags will be even stronger. I would use mesh bags for faster drying. Some external pinning will add a lot of extra strength. This is the same general advice for lightweight bags of scoria, hyper-wattle, etc. Put bamboo or rebar pins on opposite sides of the wall and tie them together tightly with baling twine or cord.

Please keep us posted on your results. Take lots of good photos and send a summary of what you learn so we can share with others.

Owen, I read in two books about using rice hulls in earth bags but not much more information was given. Since then I was under the impression that rice hulls could be used solely to fill the bags. They have R values of R3 per inch and other great characteristics. Is this an instance where rice hulls could be used in lieu of wood chips with clay? Also rice hulls in my area of the country and free. Any clarification or direction on utilizing rice hulls would be greatly appreciated.

There’s very little information available on using rice hulls and so it’s hard to say how practical this method is. Be sure to protect bag walls from moisture.

Rice Hull Studio: http://www.earthbagbuilding.com/projects/ricehullstudio.htm

Nature’s Compassion domes in Pine Ridge, South Dakota: http://www.naturescompassion.com/

Also, my article on using rice hulls as insulation in suspended ceilings has just been published in issue #60 of The Last Straw Journal: http://www.strawhomes.com/