Continuing with Owen’s assessment of the Hyperadobe method of building earthbag walls, I have had some further thoughts. This innovation comes to us from Fernando Pacheco, a Brazilian engineer, and it has been used there for at least two years. I have prepared a detailed page at www.earthbagbuilding.com that is a step-by step guide to how they have been doing this in Brazil.

The use of the mesh makes the resulting wall a kind of hybrid of rammed earth, cob, adobe and earthbag building, all rolled into one. It has the advantages of all of these earthen building techniques, without many of the drawbacks. This is because the mesh allows the damp adobe soil (sand and clay) to bond with itself right through the open weave of the netting, so that the wall becomes virtually monolithic.

Rammed earth also creates a monolithic wall, but it requires the use of very strong, rigid forms on both sides into which the soil is placed and compacted; Hyperadobe uses the tube netting as the form which is then incorporated into the wall itself and helps stabilize and reinforce it.

Cob needs to be thoroughly mixed with straw to help make it cohere as a solid, monolithic material, which is then placed on the wall in small increments (cobs) so as not to deform while it cures. Hyperadobe eliminates the need for the straw because the tubular netting holds it all together. This means that the wall can be built and solidly tamped immediately without the need to wait for the material to cure, and eliminates the time and labor consuming step of mixing the straw with the adobe soil.

Adobe blocks have to be individually manufactured in forms and dried in advance of being placed and mortared onto a wall. All of this is very labor and time intensive, and is completely eliminated with the Hyperadobe method.

Conventional earthbag building, while very similar to this method, differs in several important ways. Because the polypropylene bag material (either in tubes or individual bags) is relatively slippery, it must be combined with barbed wire (usually two strands per course) between each course. Because of the friction that naturally occurs between the adjacent net material when compacted together, the need for barbed wire is eliminated, especially in vertical wall structures where the superior tensile strength of the steel is not needed.

Also with poly earthbags, it takes much longer for the fill material to dry out or cure, since it doesn’t breathe nearly as readily. This means that the Hyperadobe walls can be plastered sooner and may not need the application of separate plaster mesh because the mesh is already covering the wall. Many plasters, especially earthen plasters will adhere much more readily to the exposed soil within the netting, making the wall even more monolithic.

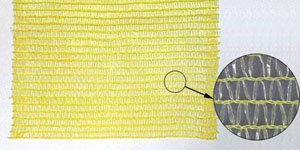

Hyperadobe uses a knit raschel, the same material used in packaging produce, which leads to less cost compared to the poly bags. Raschel is a knitted fabric which resembles hand crocheted fabrics, lace fabrics, and netting. The most common material used to knit raschel tubing is high density polyethylene (HDPE).

Hyperadobe uses a knit raschel, the same material used in packaging produce, which leads to less cost compared to the poly bags. Raschel is a knitted fabric which resembles hand crocheted fabrics, lace fabrics, and netting. The most common material used to knit raschel tubing is high density polyethylene (HDPE).

Both HDPE and polypropylene materials have poor resistance to the UV from sunlight, and must be protected as much as possible against such exposure. However the HDPE netting would have some natural protection because it become partially embedded in the fill material when tamped. The more opaque the plastic is, the more resistant it will be to UV, so if there is a color choice, black is the best.

This is an exciting development and I predict that it will catch on quickly and eventually become a dominant building method around the world!

could the fruit bags be used to hold scoria or perlite? maybe it is not strong enough and will break open? maybe the courses will not bind together like adobe and barbed wire will be needed anyway?

Perlite would fall through, but 1/2″ scoria would work. You’ll need barbed wire. And it helps to tie courses together with twine for added stability.

http://www.fruitgrowers.com/pgs/Packaging.php?cat=8

The Fruit Growers Supply Company is located out in CA. They don’t manufacture the bags but it seems you can purchase from them.

Just Google Fruit packaging supplies or potato packaging supplies and you should get a selection to choose from that is closer to you.

Not sure what the shipping would be but some of the manufacturers in China are cheap! .01-.02 a bag. The weights of the rolls don’t seem too bad either. Around 2 kg = 4.4 lbs.

Thanks Chris.

This Hyperadobe looks great! Do we know of any tube distributors of this material yet in the US?

Not yet, but obviously there’s at least one US supplier because the bags are used to pack fruit and vegetables. It seems like California is the most likely place to look due to the large agricultural production in the area.

Also note, I’ve seen some bags that have 3/8″x3/8″ mesh grid made of threads. Soil would probably fall out of these larger openings.

Another option is to email the major suppliers in China and ask for contact info of US distributors. All it takes is one good source… In fact, I’ll donate one free copy of my upcoming book to whoever locates a US supplier of raschel mesh bags first. (Must be a type of bag that will work in earthbag building.)

Owen,

I saw the Earth Building documentary that you posted and LOVED it. The section on Adobe building the young lady made the comment that they have 100s of layers of plaster from repair. In my mind it turns me off to adobe because I feel it needs yearly repairs. I don’t feel like that about Cob or Earthbag building.

My question is will the hyperadobe have the need for constant repairs like adobe or will it hold up like earthbag? Also, am I just mistaken? Does earthbag, cob, rammed earth all need yearly maintenance just like adobe? Because you never read articles about the yearly maintenance required for these types of buildings.

Any structure that’s exposed to the elements will need more frequent repair. That’s why it’s important to have large overhangs to protect walls. Add extra protection on the windward side with plantings, trellises, privacy walls, etc. to slow blowing rain. Raise the walls above the where moisture will cause damage. Example: use stone along the base if you have strong blowing rain or deep snow. If the walls are protected like this, then cob, adobe, earthbag etc. can last for many years without wall or plaster maintenance.

One thing that caught my attention in the original video by EcoOcha (the first video shown in the link at the beginning of the article above) was that they not only tamped the top of the tube, but the sides as well, to reduce the ‘log cabin’ look and to reduce the amount of plaster infill required. This smoother surface would be much easier to plaster.

Yes, more and more builders are flattening the walls like this to save plaster work. It’s strange, but for some reason some people say this doesn’t work, that the bags will crumble if you tamp the sides. Maybe their soil has less clay. I don’t know, but it works great for us and for others.

One thing is for sure — if you don’t at least try to flatten the walls somewhat then you’ll have to apply a massive amount of plaster to even out the walls. That would take a great deal of time, effort and materials.

Kelly, I live in a colder climate. Would you envision a smaller tube INSIDE the main tube for insulating material? Say a 4 or 5 inch tube of perlite facing the outer wall held in place by two layers of fabric and the fill material.

Maybe Kelly has time to add his comments. In the meantime, take a look at this article: http://www.earthbagbuilding.com/articles/insulated.htm

You want the insulation on the exterior and the thermal mass on the interior for optimum results.

Another option is to fill the bags or tubes with scoria, etc. like Kelly did.

That’s great news, Kelly, looking forward to reading more about this development. We’re hoping to build next year (in the Northeast) and researching all the cold/wet weather options, may start with a test workshop/greenhouse dome to see what works.

I’d imagine you need to get the mix consistently right tube by tube so it doesn’t dilute the rows below as it’s tamped down.

Exciting!

Could also still use barbwire for the corbeling part of domes, right? Do the mesh bags seem like they’ll have enough tensile strength to hold the loads during corbelling? Looks like they stretch more than poly bags.

I imagine spray-on insulation would work better with this mesh tooth to grab on to also, or your papercrete for example.

Love following this blog, it’s like going back to school.

We’re investigating to see if anyone has built domes with this mesh.

Yes, the mesh stretches slightly. But that’s a good thing because the smaller mesh bag I tested expanded to nearly the exact size of our poly bags. (Different brands may produce different results.)

Upper courses will not “dilute” lower courses, because the moisture content is quite low — just moist enough for the clay to bind the aggregates. Add moisture gradually as you mix your soil until you develop an eye for the right moisture content. If it looks wet and shiny, or if water oozes out, then there’s too much water. If it crumbles apart when tamped then it’s too dry. A garden spray nozzle is good for this purpose.