Yesterday’s blog post about Rex’s Pallet House got me thinking of some different possibilities. Rex and the crew have done an outstanding job so far of building a solid, durable home at incredibly low cost (around $4/sq. ft.). One could stop right there, follow in Rex’s footsteps and be quite satisfied with the results. But I’m the type of person who likes to run ‘what if’ scenarios to explore multiple options. (Brainstorming is free and fun, and often leads to improved results.) For instance, not everyone has 6 months available to build their home. Some builders might prefer spending a little more money to reduce the labor and speed construction. $4/sq. ft. is so cheap, that many could probably afford to pay a little extra, so let’s briefly look at some alternative building methods that will raise the cost a little, without breaking the bank.

Here are a few ways to speed construction at slightly higher cost:

– You could buy poles instead of spending days cutting and dragging them out of the woods. Besides saving a lot of time and hard work, you could also eliminate the need for a chainsaw. Rot resistant woods such as juniper and cedar, and osage orange and black locust work best. These woods can last over 100 years even when buried directly in the ground without concrete. Poles like these are often available at auctions, farm sales, Craigslist and ‘thrifty nickel’ classified ad newspapers. You might even be able to trade work or barter for the posts.

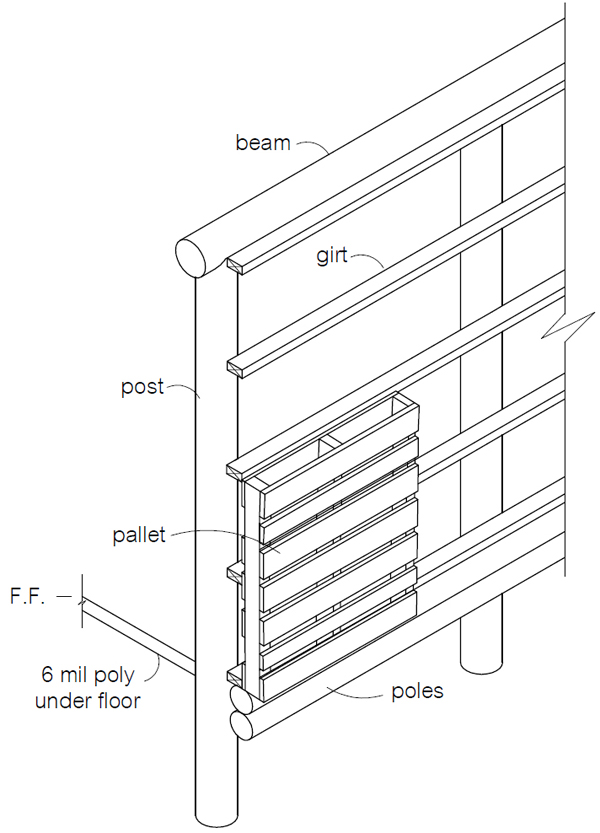

– Use rot resistant poles along the base of the walls instead of building a foundation (see drawing above). You might want to add some pallet wood to cover the gaps between poles. See the earth berm/plastic sheeting suggestion below to help prevent moisture problems.

– You could use gravel bags (sand bags filled with gravel) for the foundation. This fast, relatively easy foundation system should be less expensive than making stone/cement foundations. Here’s one of numerous links on building with gravel bags.

– Use full pallets instead of cutting them apart. This might require some extra lumber for bracing, but it saves time and effort. Our Natural Building Blog has lots of info about building with pallets. Previous blog posts can be found by using the built-in search engine on the right side of the page. Here are two links to get you started: Post and Beam Pallet Walls and Double Pallet Wall with Post and Beam (for cold climates).

– Fill the space inside the pallets with recycled styro packaging ‘peanuts’ for low cost wall insulation. Yeah, it’s not 100% natural and so it’s not perfect. But styro peanuts are often available for free, and it’s much faster to pour this material in the walls than mixing and packing adobe or padobe inside the pallets. Or you could use rice hulls or maybe splurge a few hundred dollars and buy cellulose insulation.

– Use typical earthen plaster on the surface of walls instead of thick earthen walls. This is what many natural builders do to save time and effort. You might want to add plaster mesh over the pallets for a stronger bond. The mesh would contain the wall insulation and provide something for the plaster to grab onto.

– Berm only about 30” high. This will provide most of the energy saving benefits you’re after with less work and fewer problems ( less pressure on the walls) than fully bermed houses. Add two layers of 6 mil polyethylene sheeting for moisture protection.

– Buy trucked in soil versus digging it by hand. Even if you enjoy hand digging like I do (it’s fun to see how fast you can fill a truck… or least it was when I was 20 years old), be sure to count the cost of your time. Building a house is very labor intensive and time consuming. Look for ways to improve efficiency. Fill dirt is usually very affordable and in most cases will be more cost effective than hand digging. (Note: I think Rex is way out in the sticks where trucking soil is not practical. His closest neighbors are wild pigs and rattle snakes. I think he said they have a tractor.)

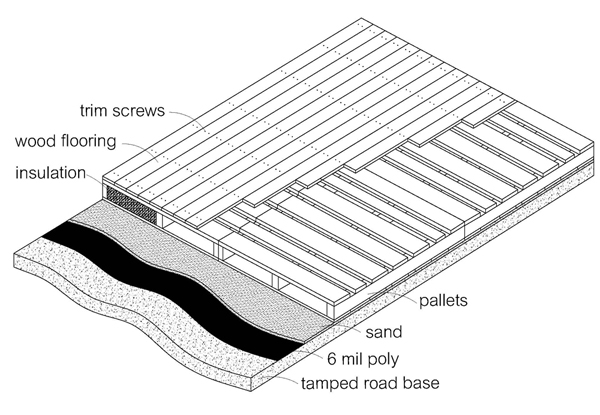

– Flooring options: Rex is going to build natural stone floors. It would be hard to beat stone floors for beauty and durability, but they are time consuming to build. Faster options include recycled brick or compressed earth blocks (CEBs) set in a bed of sand. Also consider pallet floors and pallet wood flooring. Brick floors excel for entryways and baths.

– Buy decent quality salvaged lumber or rough sawn lumber from a local sawmill instead of cutting apart pallets.

– Consider hiring one or two workers for the most difficult parts of the job, such as the roof. Hiring workers will definitely increase the cost, but the idea here is “many hands make light work”. Plus, you may not be able to get free helpers or do everything by yourself. You may even lack some tools and ladders. Know your limitations and plan accordingly. There are lots of unemployed or underemployed construction workers right now and you might be able to strike a good deal. In most cases, you’d want to be on the jobsite the entire time and oversee every step to reduce mistakes and problems. The time savings could be substantial. You and two moderately skilled workers could build the entire roof in a few days instead of a few weeks.

Conclusion: So how much extra cost are we talking about? That depends on what options you go with, and the cost of materials and labor in your area. You’ll have to make a detailed cost estimate to figure out accurate costs. (Actually, do multiple cost estimates – paper is cheap, and carefully planning will pay for itself 10 times over.) But as a quick estimate, you could build in the neighborhood of $10-$15/square foot if you’re very frugal (and have few or no building codes like Rex). For a 720 sq. ft. house, that’s around $7,200 – $10,800. Not bad, not bad at all. Beats the heck out of spending the rest of your life paying for banker financed mass produced crap housing, that’s for sure. And, just as importantly, you might be able to slash the construction time in half.

Comment: This project is so engrossing that I find myself reading Rex’s emails over and over. This seems like the best project in the last year or so. I’m definitely looking forward to the next update. Maybe we should have a poll on our blog where readers can vote for their favorite natural building project.

hi owen, great post.

sorry this is not related but i have been trying to get in touch with you to talk about having some building plans made up. i have sent a couple emails over the last week and not heard back. are you still replying to strawhouses[at]yahoo.com ?

thanks

My new email is naturalhousesAT gmail.com

I updated my contact info on our About Us page and published a blog post a while back announcing the change.