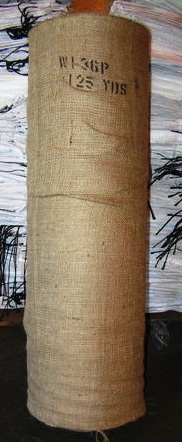

I stumbled on a website – Central Ohio Bag and Burlap, Inc. — that sells “plain” (presumably untreated) burlap in rolls. This opens the possibility of buying or making burlap tubes. This company carries the right size. (Try to find a company nearby to reduce shipping costs.) They have 40” wide rolls of burlap that would make tubes about 19” wide. Many suppliers handle special orders such as this, but no one has made burlap tubes to my knowledge. Please email us if you hear of someone building this way.

From their website:

40” width 7 oz. untreated rolls sold in lineal yards (LY)

125 LY– $110 = .88/LY or .29/lineal foot

250 LY — $215 = .86/LY or .28/lineal foot

(not including fee for sewing tubes)

Most earthbag builders are using polypropylene bags or tubes due to its strength, cost and greater durability. Lately, there’s been a lot of excitement over mesh bags and tubes (hyperadobe). However, I’m always hoping for a 100% natural solution (even though earthbag building is already incredibly low impact and sustainable). See Natural Fiber Bags. But for greatest durability bags/tubes of natural fibers would have to be stabilized using something like lime, caliche or alker technology.

Here’s another lead. NYP Corporation sells burlap for many applications and can handle custom orders such as sewing rolls into tubes.

Image credit Central Ohio Bag and Burlap, Inc.

Dear Sir/Madam,

Good day to you. Hope you are well.

I am Sarwar Hossain, Proprietor of “Sunzamul Jute Impex” in Bangladesh.

We have been exporting Jute products to various countries with good reputations for a long time.

The products that we are regularly exporting abroad such as: Jute Fabrics, Jute Webbing, Jute Nursery Tape, Jute Nursery Sheets, Camouflage Burlap, Jute rope, Jute Felt, Jute yarn, Jute ball, Jute sack and Hessian jute bags.

For more information please visit our website: http://www.sunzamuljute.com

If you currently have any inquiry then you can email us directly without any hesitation. We can provide you with 100% export quality products and competitive prices.

We are looking forward to hearing from you soon.

Kind regards

Sarwar Hossain (Proprietor)

Cell & WhatsApp: +8801755643541

—

SUNZAMUL JUTE IMPEX

Bangabandhu Avenue, Gulistan Road,

Khaddar Bazar Complex (5th floor),

Room#306, Dhaka-1000, Bangladesh.

E-mail: info@sunzamuljute.com

sunzamuljute@gmail.com

Web : http://www.sunzamuljute.com

NYP Corporation has untreated burlap tubes: http://nyp-corp.com/spiral-tubing

The price is about $1/yard for an 18″ diameter though.

That’s great to hear.

I have a question that I’m going to ask here, even though it’s not directly related to this post.

I’m in the process of scavenging bags, but also have been offered 1250 lnft of polypropylene tubing at a great price. Could I combine tubing and bags, and if so, what would be the best way to do this?

Thanks!

Sure, just make sure they’re the same width or the plaster job will be more difficult and costly. You could arrange the bags and tubes any way you want, although I would use bags for the gravel bag foundation. They would be easier to fill with gravel than tubes.

Here’s an email from Jozef. But what happened to Jozef shouldn’t happen with untreated burlap.

“I’ve used burlap bags for EB building in the past. I got them from coffee roasters, rice baggers… U name it. I even got a bolt of burlap material from a seamstress and used that. There is good friction between the bags but one thing I noticed, over a short time the first coat of earth plaster ( natural, lime or cement based) tended to separate from the burlap, regardless of recipe.

I was doing some mushroom cultivation in burlap and straw, at that time and had very few success in getting “flushes” ( mushroom production) although the mycelium (roots) would grow on the straw. I couldn’t figure out why. Went over my methodology over and over. The only step I skipped was washing the burlap. I asked around and found that burlap is often treated with an oil wash.., everything from kerosine to petrol was used to prevent the burlap from degrading over time. I went to a fabric store and pulled some burlap off the shelf and smelled it. There was a distinct smell of diesel on the fabric.

This oil interface could account for the plaster separation.

To counter this measure, instead of washing I put some detergent in with the top coat, or I sprayed the surfaces to be coated with a soap wash. This remedied the problem.”

Jozef

I’m not too familiar with burlap. Wouldn’t it rot over the years from the moisture of the soil inside the bags? Also, wouldn’t this be more expensive than poly bags? On a side note, I’m working on an idea for incorporating some sort of dehumidifier system built into the EB house that supplies the homeowner with fresh drinking water directly filtered from the air. Have you ever thought of this and/or do you have any thoughts or ideas on this?

Yes, it would probably rot. That’s why I suggested stabilizing the soil.

Yes, probably more expensive. But some may be willing to pay extra for 100% natural products.

I’ve read about devices that make water from air. You’ll have to do your own research on that.