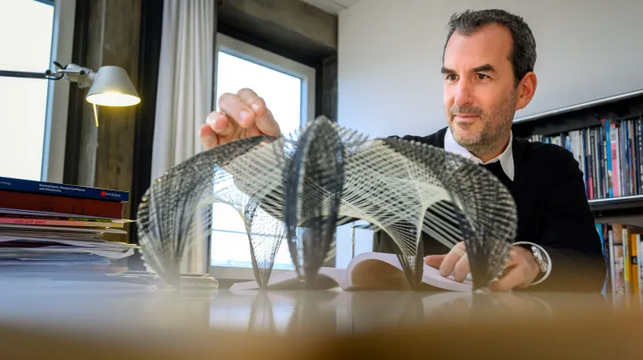

Wood is inherently imprecise. Its grain reverses and swirls. Trauma and disease manifest in scars and knots. Instead of viewing these natural tendencies as liabilities, Achim Menges, an architect and professor at the University of Stuttgart in Germany, sees them as wood’s greatest assets.

Menges and his team at the Institute for Computational Design and Construction are using computational design—which relies on algorithms and data to simulate and predict how wood will behave within a structure long before it is built.

Menges and his team at the Institute for Computational Design and Construction are using computational design—which relies on algorithms and data to simulate and predict how wood will behave within a structure long before it is built.

Menges’s recent work has focused on creating “self-shaping” timber structures like the HygroShell, which debuted at the Chicago Architecture Biennial in 2023. Constructed from prefabricated panels of cross-laminated timber, HygroShell morphed over a span of five days, unfurling into a series of interlaced sheets clad with wooden scale-like shingles that stretched to cover the structure as it expanded.

Menges’s recent work has focused on creating “self-shaping” timber structures like the HygroShell, which debuted at the Chicago Architecture Biennial in 2023. Constructed from prefabricated panels of cross-laminated timber, HygroShell morphed over a span of five days, unfurling into a series of interlaced sheets clad with wooden scale-like shingles that stretched to cover the structure as it expanded.

Its final form is a delicately arched canopy that rises to nearly 33 feet (10 meters) but is only an inch thick. Self-shaping could offer industrial-scale production of curved mass timber structures for far less cost.

Its final form is a delicately arched canopy that rises to nearly 33 feet (10 meters) but is only an inch thick. Self-shaping could offer industrial-scale production of curved mass timber structures for far less cost.

“What we’re trying to do is develop design methods that are so sophisticated they meet or match the sophistication of the material we deal with,” Menges says.

“What we’re trying to do is develop design methods that are so sophisticated they meet or match the sophistication of the material we deal with,” Menges says.

Using robotic machinery to prefabricate the structures, Menges’s process allows for thin-walled timber construction that saves material and money. If they were self-shaped, curved elements could halve the material requirements for certain structural features in a multistory timber building, Menges says. “You would save a lot of material simply because curvature adds stiffness. That’s why we see everything is curved in nature.”

Using robotic machinery to prefabricate the structures, Menges’s process allows for thin-walled timber construction that saves material and money. If they were self-shaped, curved elements could halve the material requirements for certain structural features in a multistory timber building, Menges says. “You would save a lot of material simply because curvature adds stiffness. That’s why we see everything is curved in nature.”

His interest in self-shaping structures was inspired by pinecones, which—long after falling from trees—retain the biological programming to open and expose their seeds as temperatures rise. “That’s a plant motion that does not require any motors, nor does it require any muscles,” Menges says. “It is programmed into the material.” Pinecones made him realize that materials like wood can be manipulated to carry out specific behaviors that are hard-coded in their DNA as a response to a stimulus.

His interest in self-shaping structures was inspired by pinecones, which—long after falling from trees—retain the biological programming to open and expose their seeds as temperatures rise. “That’s a plant motion that does not require any motors, nor does it require any muscles,” Menges says. “It is programmed into the material.” Pinecones made him realize that materials like wood can be manipulated to carry out specific behaviors that are hard-coded in their DNA as a response to a stimulus.

Menges has used self-shaping techniques to create proof-of-concept projects like the Urbach Tower, a 45-foot spiraling wood structure overlooking the fields of the Rems Valley near Urbach, Germany. Instead of using energy-intensive mechanical processes that require heavy machinery, the team prefabricated a dozen curved, self-shaped wood panels and assembled them on site, reducing the time it would otherwise take to build such a structure.

Menges has used self-shaping techniques to create proof-of-concept projects like the Urbach Tower, a 45-foot spiraling wood structure overlooking the fields of the Rems Valley near Urbach, Germany. Instead of using energy-intensive mechanical processes that require heavy machinery, the team prefabricated a dozen curved, self-shaped wood panels and assembled them on site, reducing the time it would otherwise take to build such a structure.

Menges used self-shaping to design a system of 3D-printed wooden window blinds that opened and closed in response to changes in relative humidity. Embedded in the wood shell is a solar gate that closes in warm weather, shading the space, and opens during colder months to provide passive solar heating. Compared with a conventional timber building, this structure has half the environmental impact over its life cycle.

Menges used self-shaping to design a system of 3D-printed wooden window blinds that opened and closed in response to changes in relative humidity. Embedded in the wood shell is a solar gate that closes in warm weather, shading the space, and opens during colder months to provide passive solar heating. Compared with a conventional timber building, this structure has half the environmental impact over its life cycle.

Menges’s work is coming at a time when the sustainability of mass timber buildings—those with structural components made from engineered wood instead of steel or concrete—is under scrutiny. Concerns range from where the timber is sourced to whether preserving forests sequesters more carbon than harvesting them for building material, even if building with wood reduces carbon emissions relative to producing concrete and steel. There are also worries about what happens to all the wood left behind during the logging process. Trees may be a renewable resource, but they require decades to mature and are already threatened by climate change. That’s what led Menges and others to advocate for more efficient building practices that don’t waste wood.

Menges’s work is coming at a time when the sustainability of mass timber buildings—those with structural components made from engineered wood instead of steel or concrete—is under scrutiny. Concerns range from where the timber is sourced to whether preserving forests sequesters more carbon than harvesting them for building material, even if building with wood reduces carbon emissions relative to producing concrete and steel. There are also worries about what happens to all the wood left behind during the logging process. Trees may be a renewable resource, but they require decades to mature and are already threatened by climate change. That’s what led Menges and others to advocate for more efficient building practices that don’t waste wood.

“A tree does not have a defect,” he says. “It’s an anatomical feature. What we need to learn is what kind of building systems we develop that integrate these features, and not strive for the homogeneity that is simply not there.”

“A tree does not have a defect,” he says. “It’s an anatomical feature. What we need to learn is what kind of building systems we develop that integrate these features, and not strive for the homogeneity that is simply not there.”You can read the original article at www.technologyreview.com