When you stand beneath Mizzi Studio’s mushroom-like pavilion at Carbon Garden in London on a sunny day, light filters through the flax and resin cap of this mysterious “fruiting body,” as founder Jonathan Mizzi describes it. “The material has this lovely translucent quality,” he says. “When you stand under it, you become held in this subsurface scattering of light.”

The flax fibers are part of a palette of natural materials Mizzi Studio chose for the pavilion, a showcase of the essential role that plants and fungi play in tackling climate change. “It is born from the belief that our future must be grown from renewable, natural materials,” he says of the structure, which rises from a granite base, with a glulam timber trunk and frame supporting the precast panels of flax and resin. “We wanted to go beyond just choosing low carbon materials, adding those that sequester carbon and help regenerate nature.”

The flax fibers are part of a palette of natural materials Mizzi Studio chose for the pavilion, a showcase of the essential role that plants and fungi play in tackling climate change. “It is born from the belief that our future must be grown from renewable, natural materials,” he says of the structure, which rises from a granite base, with a glulam timber trunk and frame supporting the precast panels of flax and resin. “We wanted to go beyond just choosing low carbon materials, adding those that sequester carbon and help regenerate nature.”

Flax is one of the oldest continuously cultivated plants in the world. When grown in a climate responsible fashion, the benefits of this fast-growing plant are many: the cultivation of one hectare of flax can sequesters 3.7 tons of CO2 and its long, fibrous roots can detoxify the soil and improve hydration. Meanwhile, it requires no herbicides, pesticides or irrigation when grown in its ideal geographical zone, such as parts of western Europe.

Flax is one of the oldest continuously cultivated plants in the world. When grown in a climate responsible fashion, the benefits of this fast-growing plant are many: the cultivation of one hectare of flax can sequesters 3.7 tons of CO2 and its long, fibrous roots can detoxify the soil and improve hydration. Meanwhile, it requires no herbicides, pesticides or irrigation when grown in its ideal geographical zone, such as parts of western Europe.

Linoleum, a natural, recyclable flooring material made with solidified linseed oil from flax seeds. Linoleum is like playdough: it can be remolded over and over again.

Linoleum, a natural, recyclable flooring material made with solidified linseed oil from flax seeds. Linoleum is like playdough: it can be remolded over and over again.

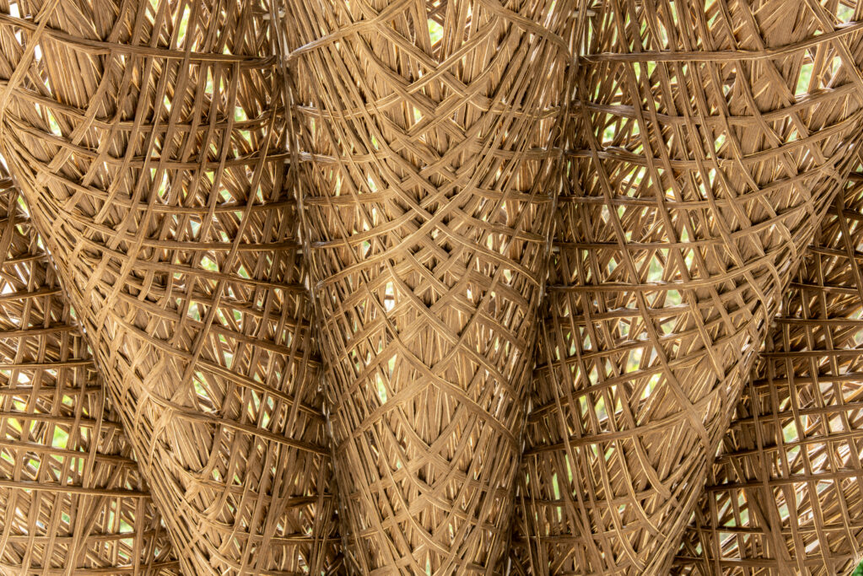

Architects are adopting flax as an alternative to energy-hungry carbon fiber. In 2021, researchers and engineers at Stuttgart University completed the livMatS Pavilion, the first load-bearing structure made from robotically woven flax, with biologists from the University of Freiburg. In the pavilion, the flax fiber is wound into a truss structure, with corner reinforcement and structural bracing. The fibers add rich texture to the design, while the robotic weaving ensures material efficiency.

Architects are adopting flax as an alternative to energy-hungry carbon fiber. In 2021, researchers and engineers at Stuttgart University completed the livMatS Pavilion, the first load-bearing structure made from robotically woven flax, with biologists from the University of Freiburg. In the pavilion, the flax fiber is wound into a truss structure, with corner reinforcement and structural bracing. The fibers add rich texture to the design, while the robotic weaving ensures material efficiency.

But natural fibers come with challenges. The big issue with flax and other natural materials such as hemp is their high variability and the uncertainty of their mechanical properties, unlike with steel or concrete. To mitigate this, ITKE combined woven flax with timber for its latest structure, the 2024 Hybrid Flax Pavilion. Its undulating roof is the first-ever melding of cross-laminated timber plates and natural fiber bodies produced through coreless flax filament winding, resulting in a column-free space below.

But natural fibers come with challenges. The big issue with flax and other natural materials such as hemp is their high variability and the uncertainty of their mechanical properties, unlike with steel or concrete. To mitigate this, ITKE combined woven flax with timber for its latest structure, the 2024 Hybrid Flax Pavilion. Its undulating roof is the first-ever melding of cross-laminated timber plates and natural fiber bodies produced through coreless flax filament winding, resulting in a column-free space below.

Another barrier to uptake is the costly certification hoops and warranty hurdles that building with new materials requires—especially challenging when working on public buildings.

Another barrier to uptake is the costly certification hoops and warranty hurdles that building with new materials requires—especially challenging when working on public buildings.

The above projects incorporate resins derived from fossil fuels due to the prohibitive cost of bio alternatives and questions around their durability but, as demand increases, their cost and quality will improve.

The above projects incorporate resins derived from fossil fuels due to the prohibitive cost of bio alternatives and questions around their durability but, as demand increases, their cost and quality will improve.

You can read the original article at metropolismag.com

You can read the original article at metropolismag.com