This article describes a low cost method of building insulated basement walls without concrete, using geotextiles. Typical basement walls are expensive and use large amounts of concrete, a major contributor to global climate change. Concrete basement walls are typically built by contractors, because they require expensive forms and specialized knowledge. Plus, in cold climates they require insulation to reduce heat loss. Rigid foam board insulation is most commonly used to insulate basements, but this unfortunately has an environmental toll. All these things lead to expensive, energy intensive basement walls that strain the environment. Obviously there’s a need for low-cost, more sustainable alternatives.

The earthbag/geotextile basement wall system described here has excellent potential to save on initial construction costs and long-term energy costs. And again, no concrete is used. However, this system is experimental — none have been built yet. Even though it is untested, the basic concept utilizes well proven geotextile retaining wall technology. The same principles have been used to build retaining walls along roads, highways and elsewhere for decades. But no one to my knowledge has used this technology for basement walls.

You can read the entire article at Mother Earth News Blog.

Was wondering the difference between straight and leaning outward walls?… We r going to do a earthbag house and covering it up with soil, like a Hobbit house ..

Basement walls that lean out are somewhat more stable than vertical ones, but it depends on the engineering whether it might be necessary.

what are the standard specification of geo textile bags used for this basement system. Can these geotextiles also be used for the main building structures as well.

You can use regular polypropylene earthbags or raschel mesh tubes or bags (often called hyperadobe) for the walls. In addition to the article, our blog has everything you need to know. Search for terms such as ‘raschel mesh’ for example. I don’t have the geotextile details, but you could explain what you’re doing to any geotextile supplier and I’m sure they can provide what’s needed. It’s the same material used to build retaining walls for decades.

This blog is very informative and it really gives me the information that I am looking for. Thanks a lot admin.

Very smart and easy instalation with geotextiles. It must be very cheap.

Geotextile Wall

Very smart how long time will these walls stand before they must be replaced?

They can last indefinitely since the geotextile is not exposed to sunlight. That’s why they meet code for highways. The US highway administration tested them to at least 500 years. There’s an excellent geotextile magazine available for building professionals. There’s a whole industry that specializes in industrial geotextiles. http://geosyntheticsmagazine.com/materials/geotextiles

Hello dear sir/madam

we are big contractor company and we have very big market and contracts for all geotextile and geomembrane products. So, this is our pleasuer we knew your company recently and hope we can open good business with you.

right now we are looking

Nonwoven Geotextiles 300 GRAM

Silt Fence

Agricultural Fabric

Protection of silage from adverse weather

Stimulates temperature and microbe growth in composting applications

Winter protection of plants and straw etc

Temporary coverage of bare erodible slopes

Envirocell M / MP Geocell

GCL 3 OR 4 KILOGRAM

Envirofelt CO Turf Reinforcement Mat (TRM)

Soil erosion protection of steep slopes

Above water level riverbank protection

Water runoff channels, spillways, canal linings

Improve bearing capacity of foundation platforms

Facings of geosynthetic reinforced soil slopes and vertical structures

0060172956916

THANK YOU VERY MUCH

KAMRAN

are these geotextiles UV resistant?

They wouldn’t have to be since they’re underground. They would only be exposed to UV for a short time during construction. For very large jobs, you can order UV resistant materials or coat the bags as you go with cheap recycled latex paint.

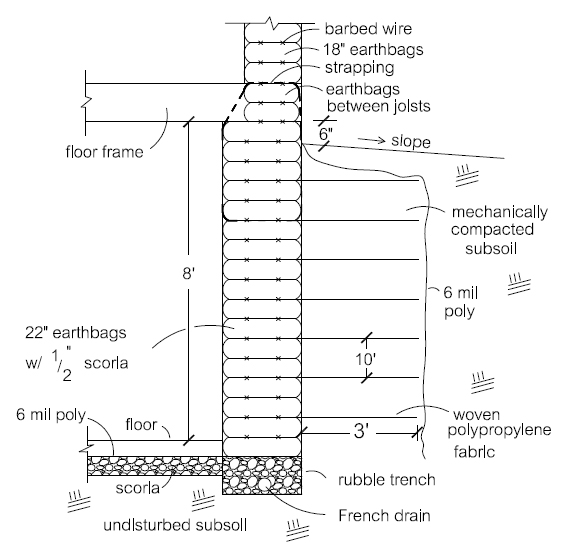

The strapping is a little difficult to see, sorry. It goes under about 5 courses of 22″ earthbags. Regular nylon strapping used to secure loads on pallets works great.

Not shown: 2×4 plate pinned to lower bags. Build the floor frame on the plate.