UC Davis designed a CoolBot cool room (excellent project for homesteaders!) using rice hull concrete for insulation and a CoolBot controller to keep farm produce fresher. The cool room paid for itself the first year and even helped make a good profit for local farmers. The rice hull concrete was poured into forms to make insulating wall boards. This blog post will briefly summarize the outcome of their project. The full report is available online for free and can be found by searching for the title of the report: Cool room insulation – UC Davis D-Lab

green concrete

SpaceCrete (Formless Vertical Concrete)

This method allows concrete to be pumped into place to build walls without forms. Redimix concrete is delivered to the jobsite, then thickeners and accelerators as required are injected and intermixed in the pumping line, to give the fluid concrete the zero-slump-with-workability properties that you can see here.

Ferrock Concrete

“David Stone is the brains behind a new patented concrete technology known as Ferrock, based on iron carbonate and incorporating largely recycled materials to produce (around 95%)! It’s showing promising signs as an alternative to concrete and a far greener building material.

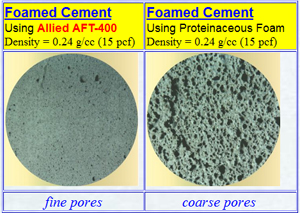

Foamed Lightweight Concrete

Natural builders strive to reduce their use of cement due to high cost and adverse environmental impacts. Sustainability conscious natural builders might use ferrocement, cement plaster or micro concrete roofing tiles which use relatively small amounts of cement, and avoid more concrete intensive materials such as concrete block. Foamed lightweight concrete is another material that could be added to the list of green building materials.

Roman seawater concrete holds the secret to cutting carbon emissions

This discovery shows how to make stronger, longer lasting concrete with far less energy. A green type of concrete like this could replace Portland concrete, which is viewed negatively by many due to its adverse environmental impact.