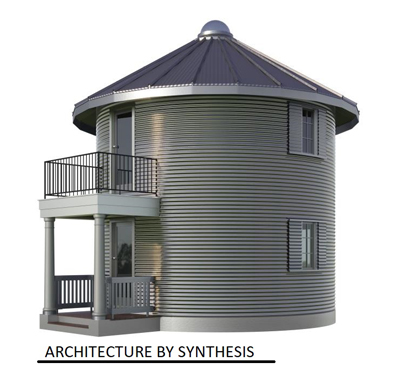

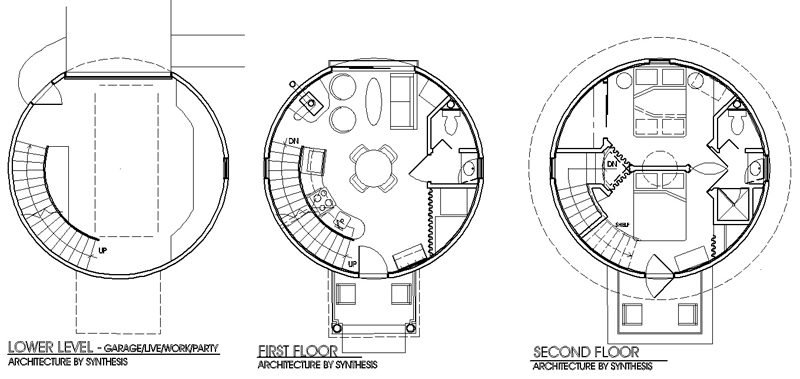

Mark Clipsham has come up with some new plans for affordable grain bin houses. According to Mark, the basic construction of these homes is fast and DIY friendly. There is no concrete foundation wall – the home’s wall construction is the same from the footing to the roof. They are monolithic/continuous, field-formed, self-supporting SIPs (no framing in the walls or roof). They outperform traditional construction in every respect (cost, speed of construction, strength, no maintenance, thermal performance, resistance to disasters and typical building failures) by a healthy margin. These are not a compromise but an upgrade. They are built on the same principle as high-performance coolers. The electric and plumbing on the exterior walls are accessible without demolition after they are built. 346 SF per bin per floor.

Mark Clipsham has come up with some new plans for affordable grain bin houses. According to Mark, the basic construction of these homes is fast and DIY friendly. There is no concrete foundation wall – the home’s wall construction is the same from the footing to the roof. They are monolithic/continuous, field-formed, self-supporting SIPs (no framing in the walls or roof). They outperform traditional construction in every respect (cost, speed of construction, strength, no maintenance, thermal performance, resistance to disasters and typical building failures) by a healthy margin. These are not a compromise but an upgrade. They are built on the same principle as high-performance coolers. The electric and plumbing on the exterior walls are accessible without demolition after they are built. 346 SF per bin per floor.

You can dress these homes up or leave them minimal. Or start as minimal and finish them as funds and time becomes available inside and out along with upgrades and additions. These are designed to last hundreds of years. With a floor or two above the main floor there is the opportunity for extended family, rental income or live in healthcare. One plan shows a bedroom on one side and office/entertainment room on the other that can be turned into a guest room quickly and easily.

You can dress these homes up or leave them minimal. Or start as minimal and finish them as funds and time becomes available inside and out along with upgrades and additions. These are designed to last hundreds of years. With a floor or two above the main floor there is the opportunity for extended family, rental income or live in healthcare. One plan shows a bedroom on one side and office/entertainment room on the other that can be turned into a guest room quickly and easily.

The “garage” on the lower level can be used for many different things – live/work, family room, party spot, large kitchen, storage, workshop/office, a place to get away and have some quiet time or a combination of these. The deck off the first floor is designed to be waterproof so it acts as a carport or a place to entertain or display outdoors even when raining.

There is an option for using a rocket, traditional or cooking stove to heat a mass couch in front of a bay window in some plans. Window and door cut outs can be used for seriously functional shutters. Standard cabinets can be used with a curved countertop.

You can find out more about these homes or buy the plans at dreamgreenhomes.com

A few corrections of perspective, one “grain bin” and “silo” are distinctly different terms and different structures and should be treated as such. Second, grain bins are built top down, the process assembles rings and roof on the ground and as rings are added by the use of bin jacks will be at the top of the structure.

David Shelgren,

Mechanized Agriculturalist

Hello my wife and I are interested in having one of these silo homes what is approximate cost &sizesAnd what comes with these homes?

We only sell the plans for these grain bin homes; the size is 346 SF per bin per floor and the cost varies depending on location, amenities and labor.

They are grain bins not silos. Without more information the answer – without being funny is: How high is up? The same project in “my backyard” vs San Diego could be as much as five times more. Size matters too – smaller SF projects are higher per SF but less total.

The client drives the design and services needed – it varies greatly from one to another. If you want something fatally predictable get a manufactured home.

These are amazing! AMAZING.

Need to find a structural engineer for “wet stamp” design to satisfy county building dept in Oregon.

Any help is appreciated.

I would try http://www.structure1.com They are in Oregon and are familiar with alternative building.

I hope the wet stamp you need is not relative to using my copyright registered system.It took twenty years and thousands of hours to figure it out – lots of devilish details.

Cliff – I am aware of the implications of modifying bins and love structural theory. I try to keep holes to a minimum in bins because they are thermal leaks – fenestration should be carefully designed and balanced.

The whole idea of using bins as I do is to KISS – I build and am put off from the layers of building needed for traditional construction and how susceptible they are to failure.

The only interaction I had with Mr Geiger was to tell him that the Sukups had stolen all of my work for the Safe T Home he was endorsing. He felt its benefit to society was more important than my intellectual property. The Sukups sit on a LARGE pile of ill-gained cash (just type in litigation after their name)- my plan was to constantly roll over the financial gains into new affordable housing developments. Knowingly endorsing unethical, immoral people at the expense of the greater good and the rightful owner is not a desirable character trait in my book. The Sukups are basically the Trumps of Iowa. The masks that monsters wear is often that of people that really care.

Mark

I yield to your expertise, experience, and professional training. I am no architect by any means so am not in your league by a long shot. So any comments or suggestions from me are from a non professional in the area. I am a KISS (keep it simple stupid) person by nature. While born in the USA I have lived the last 23 years in New Zealand so am influenced by building rules here. People need to realize every cut they make on a grain bin effects it structural stability. Changes can be made to a silo but need to be made correctly and smartly. I used to have endless discussions on various topics such as this with Owen Geiger. I miss him dearly to this day. The man was so humble but had an endless repository of common sense knowledge on building. He was a true giver and all around nice guy.

Cliff – I agree with some of what you say and in those respects you are preaching to the choir. I could write a book on this subject. GRAIN BINS are built from the top down which you described but said the opposite. You have many anecdotal preconceptions. If you’d like to know the truth as I know it (and I’ve been working with bin designs for over twenty years) write me at mc AT architecturebysynthesis.com .

My method is fast, affable and high performance and very flexible from a design standpoint. I agree do not pack a container full of arbitrary design stuff and don’t try to force a square peg in a round hole. Consensus is all fine and well with knowledgeable people – i have seen many clever fatal mistakes made regarding bin homes that my system avoids.

Kelly

One thing I often see people try to do is get creative or make it into a normal house layout with windows, walls, and patio doors. Unless you are working with a structural engineer and have a lot of money you should keep modifications to a minimum. Silo engineering has been refined for over a hundred years so it is a defined science. They are surely a proven structure that will last a lifetime as is. Silos are built from the bottom up. You put on two rings then add on the roof then with each with new ring the silo is pushed up and a new ring is added to the bottom. Silo walls get thinner as it goes up so not all rings are not the same thickness. Rather than windows consider solar tunnel lights in the roof if you have an an open plan. If you chop a silo into compartments or rooms your space will disappear quickly. Open plan is best. A silo is round use those strengths to your benefit and not try to make round walls flat. Embrace what it does and does very well. Do not try to make into something is is not and was never designed for.

Do your research. Find every silo house close to you and talk to the owners. Find out what they did right and what they did wrong or would do differently. Silos are like dome homes they don’t appeal to everyone. So when reselling it can take a while. One option you have is to disassemble the silo and move it with you. It is not portable but is relocatable. Most commercial grain bins are on a concrete pad due to the weight of the grain. You don’t need that. Some silos have wall stiffeners on the outside which can be extended to anchor the silo into the ground. You can then have a wood floor or earthen floor instead of a cement one.