Bioceramic dome technology opens a new world of possibility in architecture. The current construction industry uses four primary material families – wood, metal, concrete, and organic polymers (plastics). Chemically bonded ceramics (bioceramics) are a new class of geopolymers that enable a different kind of innovation in construction.

Bioceramic dome technology opens a new world of possibility in architecture. The current construction industry uses four primary material families – wood, metal, concrete, and organic polymers (plastics). Chemically bonded ceramics (bioceramics) are a new class of geopolymers that enable a different kind of innovation in construction.

The new material family bridges the gap between ceramic, cement, and epoxy. Bioceramic is highly crystalline with covalent and ionic bonding like ceramic, yet it’s water activated and cures quickly at room temperature like rapid cement and it’s a glue that forms molecular bonds with nearly all natural materials. Bioceramic has a very low thermal expansion coefficient and forms waterproof “cold-joints”.

The new material family bridges the gap between ceramic, cement, and epoxy. Bioceramic is highly crystalline with covalent and ionic bonding like ceramic, yet it’s water activated and cures quickly at room temperature like rapid cement and it’s a glue that forms molecular bonds with nearly all natural materials. Bioceramic has a very low thermal expansion coefficient and forms waterproof “cold-joints”.

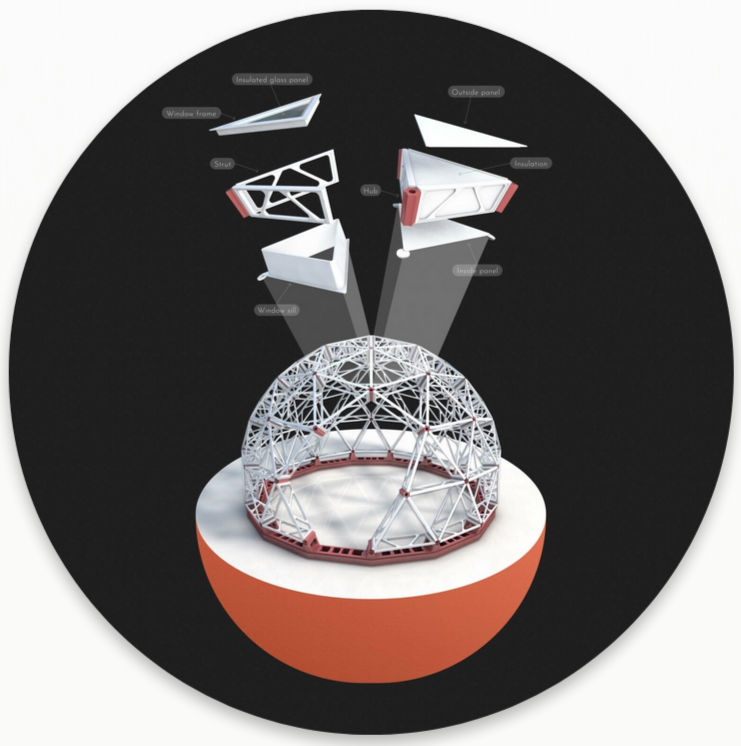

Geoship injection molds ceramic parts that are bonded together with ceramic on site. The result is an all-ceramic composite monolithic structure that maximizes efficiency through geometric precision.

Geoship injection molds ceramic parts that are bonded together with ceramic on site. The result is an all-ceramic composite monolithic structure that maximizes efficiency through geometric precision.

Bioceramic architecture eliminates nearly all construction products and whole supply chains. Roofing, tar paper, trusses, insulation, lumber, steel, concrete, adhesives, particle board, drywall, paint, and siding are all replaced with bioceramic composites.

Bioceramic architecture eliminates nearly all construction products and whole supply chains. Roofing, tar paper, trusses, insulation, lumber, steel, concrete, adhesives, particle board, drywall, paint, and siding are all replaced with bioceramic composites.

The ceramic material consists of raw earth minerals and natural fibers that react at room temperature and form a highly crystalline ceramic concrete. There is nothing to rot, rust, corrode, or burn, and no petrochemicals. Bioceramic domes are truly 100% non-toxic.

The ceramic material consists of raw earth minerals and natural fibers that react at room temperature and form a highly crystalline ceramic concrete. There is nothing to rot, rust, corrode, or burn, and no petrochemicals. Bioceramic domes are truly 100% non-toxic.

Below is an out line of advantages:

Below is an out line of advantages:

Affordable

- Low Cost

- High Efficiency

- Low Maintenance

- Fast Installation

- Small Sizes

Sustainable

- Low CO2

- Zero Waste

- 500 Year Life

- Waste Stream Use

- Recyclable

Resilient

- Fireproof

- Flood Proof

- Hurricane Resistant

- Earthquake Resistant

Healing

- 100% Non-Toxic

- Mold Proof

- Low EMF

- Resonant

- Biomimetic

You can find out more about this at geoship.is